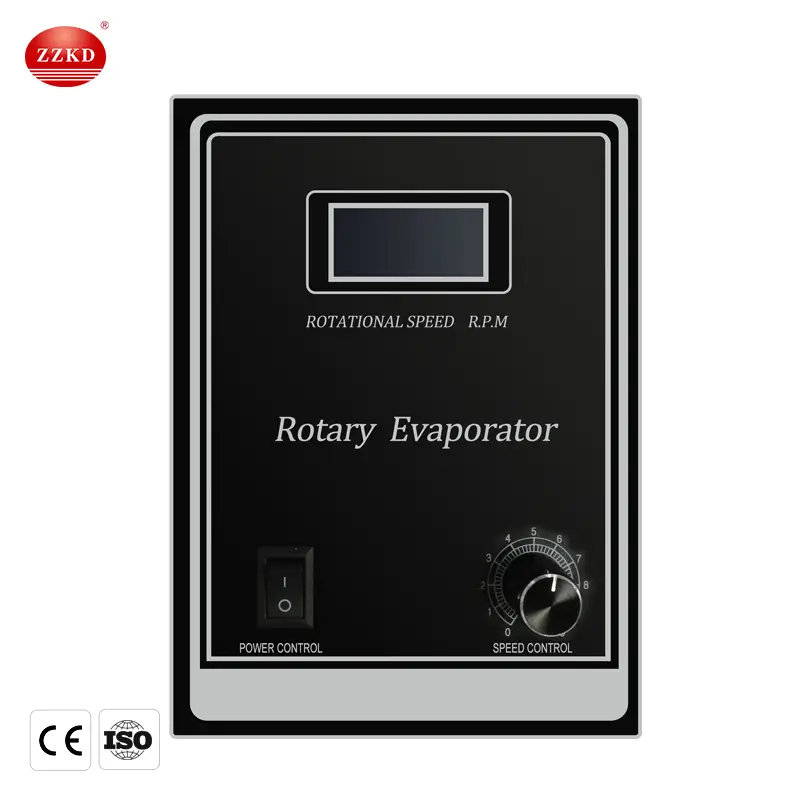

RE-201D 2L Rotary Evapoartor

The RE-201D Rotary Evaporatoris a high-performance laboratory instrument designed for efficient solvent recovery, distillation, and concentration processes. With a 2L evaporation flask capacity, it is ideal for medium-scale applications in chemistry, pharmaceuticals, and biotechnology.

Built with precision-engineered components, this 2L rotary evaporator ensures reliable operation, uniform heating, and rapid solvent removal. Its modular design allows customization with accessories like vacuum controllers or chillers, catering to diverse experimental needs. The RE-201D combines durability, user-friendly controls, and energy efficiency, making it a cost-effective solution for laboratories prioritizing productivity and safety.

Key Features of the RE-201D 2L Rotary Evaporator

1. High-Quality Construction: The RE-201D features corrosion-resistant borosilicate glass and PTFE seals, ensuring compatibility with aggressive solvents and long-term durability.

2. Precise Temperature Control: A digital thermostatic water bath (ambient to 99°C) enables precise heating for optimal evaporation rates.

3. Adjustable Rotation Speed: A 0–120 RPM stepless speed regulator ensures gentle mixing and uniform thin-film formation.

4. Safety Enhancements: Includes overheat protection, and a splash guard to minimize operational risks.

5. Efficient Condensation: A large serpentine condenser with high cooling capacity maximizes solvent recovery efficiency.

6. Compact Design: Space-saving structure with intuitive interfaces for easy integration into busy lab environments.

Applications of the 2L Rotary Evaporator

The 2L rotary evaporatoris widely used in:

1. Pharmaceutical R&D: Concentrating active compounds or purifying intermediates.

2. Chemical Synthesis: Recycling solvents like ethanol or acetone.

3. Essential Oil Extraction: Isolating volatile compounds from plant materials.

4. Food & Beverage: Removing residual solvents in flavor or fragrance production.

5. Academic Labs: Teaching distillation principles or supporting small-scale research.

Its versatility also extends to environmental testing (e.g., concentrating pollutant samples) and cannabis processing (THC/CBD purification).

Application Case

A biotech startup used the RE-201D to optimize their cannabinoid isolation process. By adjusting rotation speed (40 RPM) and bath temperature (50°C), they achieved 95% ethanol recovery from 1.5L hemp extracts in under 2 hours. The PTFE seals prevented leakage during vacuum operation (-0.09 MPa). This reduced solvent costs by 30% and accelerated daily production cycles.

Maintenance Guidelines

1. Daily Cleaning: Wipe glass surfaces with mild detergent; avoid abrasive tools.

2. Lubrication: Apply silicone grease to PTFE joints monthly to ensure smooth rotation.

3. Seal Inspection: Check O-rings quarterly for wear; replace if cracks occur.

4. Bath Care: Drain and descale the water bath every 3 months using citric acid.

5. Motor Maintenance: Avoid overloading (keep flask volume ≤80% capacity) to extend motor life.

Store the unit in a dry environment and perform annual professional calibration for optimal accuracy.

Why Choose the RE-201D?

This 2L rotary evaporator balances affordability and professional-grade performance. With CE certification and a 1-year warranty, it’s a trusted choice for labs seeking reliability. Custom configurations (e.g., explosion-proof motors) are available upon request.

FAQs

1. Why is the evaporation speed slow?

Check vacuum levels and condenser temperature; ensure no blockages in the vapor path.

2. How to prevent sample bumping?

Reduce bath temperature or rotation speed; use boiling chips if necessary.

3. What solvents are compatible?

The RE-201D works with most solvents (e.g., DCM, acetone), but avoid hydrofluoric acid or strong alkalis.

4. How to fix vacuum leaks?

Inspect seals and joints; reapply grease or replace damaged O-rings.

5. Can it handle viscous samples?

Yes, but reduce rotation speed to 30–50 RPM and increase bath temperature gradually.

Product Parameters

Technical Parameter | |||

Model | RE-301 | RE-501 | |

Evaporating flask(L) | 2 | 3 | 5 |

1 | 2 | 3 | |

Rotating motor(w) | 40 (Stepless speed regulation) | ||

Rotating speed(R/min) | 0-120 | ||

Water(Oil) Bath Power(W) | 1200 | 1500 | |

Temp control mode/range | Intelligent digital/RT-399℃ | ||

Temp resolution | ±2℃ | ||

Evaporation rate(L/H2O) | >1 | >1.5 | >1.5 |

Max.vacuum degree | |||

Lifting height(MM) | 0-120 | 0-120 | |

Water bath size | 24*15 | 26*15 | 28*17 |

Sealing mode | FTFE,fluoro rubber sealing | ||

Technical Parameter | |

Model | |

Evaporating flask(L) | 2 |

1 | |

Rotating motor(w) | 40 (Stepless speed regulation) |

Rotating speed(R/min) | 0-120 |

Water(Oil) Bath Power(W) | 1200 |

Temp control mode/range | Intelligent digital/RT-399℃ |

Temp resolution | ±2℃ |

Evaporation rate(L/H2O) | >1 |

Max.vacuum degree | |

Lifting height(MM) | |

Water bath size | 24*15 |

Sealing mode | FTFE,fluoro rubber sealing |

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China