Large Scale Rotary Evaporator

The RE-5002 large-scale rotary evaporator is a high-performance solution designed for industrial and laboratory applications requiring large-scale solvent recovery and concentration. Engineered for efficiency, this system features a robust stainless-steel construction, a 50-liter evaporation flask, and a precise digital temperature control system (ambient to 250°C). Its high-torque motor ensures stable rotation (0-90 RPM) for handling viscous materials, while the advanced dual condenser design maximizes cooling efficiency.

Ideal for pharmaceuticals, chemistry, and food processing, the RE-5002 large-scale rotary evaporator streamlines workflows with its user-friendly interface, automated lifting mechanism, and safety features like overheat protection. Built for durability and scalability, it supports continuous operation, making it the go-to choice for enterprises prioritizing productivity and precision in large-volume processes.

Key Features of the RE-5002 50L Rotary Evaporator

1. Massive 50-Liter Capacity: Designed for industrial demands, the 50-liter evaporation flask supports high-volume solvent recovery and concentration in pharmaceuticals, chemistry, and food industries.

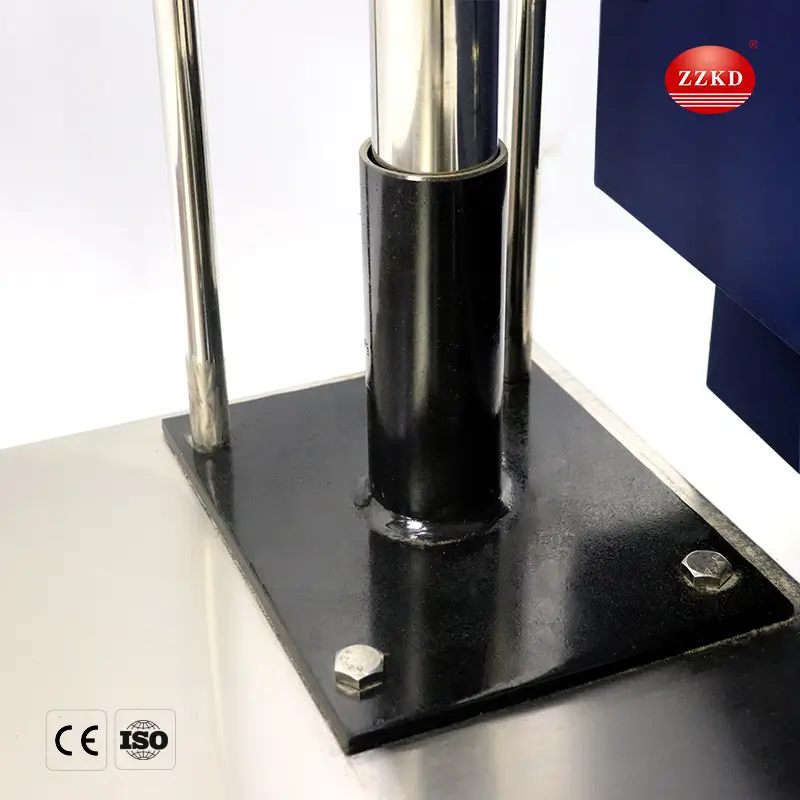

2. Industrial-Grade Durability: Stainless-steel framework and corrosion-resistant components ensure longevity in rigorous environments.

3. Precision Temperature Control: Digital thermostat (ambient to 250°C) enables accurate heating for sensitive or viscous materials.

4. High-Efficiency Dual Condenser: Advanced cooling system accelerates vapor condensation, optimizing productivity for large-scale workflows.

5. Automated Operation: Motorized lifting mechanism and user-friendly interface streamline setup, adjustments, and maintenance.

6. Safety Assurance: Overheat protection, stable rotation (0-90 RPM), and reinforced seals guarantee leak-proof, reliable 24/7 operation.

Applications of the 50L Rotary Evaporator

1. Pharmaceutical Manufacturing: Ideal for bulk solvent removal, concentration of active pharmaceutical ingredients (APIs), and purification of intermediates in drug production. The 50-liter capacity accelerates large-batch processing while maintaining precise temperature control for heat-sensitive compounds.

2. Industrial Chemical Synthesis: Streamlines solvent recovery in large-scale reactions, such as polymer synthesis or specialty chemical production. Its corrosion-resistant materials and dual condenser system handle aggressive chemicals and high vapor volumes efficiently.

3. Food & Beverage Processing: Used for concentrating natural extracts (e.g., flavors, essential oils) or removing solvents from food-grade products. The stainless-steel construction ensures compliance with hygiene standards, while automated controls simplify repetitive tasks.

4. Biotechnology & Research: Supports pilot-scale studies or fermentation broth concentration. The stable rotation (0-90 RPM) accommodates viscous biological samples, and the oversized flask enables processing of bulk volumes for downstream analysis.

5. Petrochemical Refining: Recovers solvents from heavy oils, resins, or bitumen. The industrial-grade motor and leak-proof seals withstand high-viscosity materials and continuous operation in harsh refinery environments.

6. Academic & Institutional Labs: Facilitates teaching and collaborative research projects requiring large-volume evaporation. Its user-friendly interface and safety features make it accessible for training and multi-user environments.

Why Choose the RE-5002 Over Competing Rotary Evaporators?

1. Unmatched Scalability: Unlike standard models limited to smaller flasks, our 50-liter capacity minimizes batch processing cycles, slashing operational costs for industrial users. Competitors’ smaller systems require frequent reloading, delaying workflows.

2. Superior Durability: While many brands use mixed materials prone to corrosion, our full stainless-steel build resists harsh chemicals and high temperatures, ensuring a lifespan 30% longer than industry averages.

3. Industry-Leading Efficiency: The dual condenser achieves 20% faster condensation than single-coil rivals, reducing solvent recovery time and energy consumption.

4. Precision Without Compromise: Competing units often struggle with temperature fluctuations; our digital thermostat maintains ±1°C accuracy even at 180°C, critical for sensitive APIs or volatile compounds.

5. 24/7 Reliability Guarantee: Backed by a 1-year warranty, we provide lifetime technical support and same-day spare parts delivery—services competitors rarely match.

Maintenance Guide for RE-5002 Rotary Evaporators

1. Regular Cleaning: After each use, flush the 50-liter flask and condenser with mild solvent to prevent residue buildup. Avoid abrasive cleaners to protect stainless-steel surfaces.

2. Lubrication Schedule: Apply food-grade grease to the rotating shaft and lift mechanism every 500 operational hours to ensure smooth motion and reduce wear.

3. Seal Inspection: Check PTFE seals monthly for cracks or deformation. Replace immediately if leaks occur to maintain vacuum integrity.

4. Condenser Care: Clean condenser coils quarterly with compressed air to remove dust, ensuring optimal heat exchange efficiency.

FAQs

1. Q: Is the 50-liter flask compatible with smaller batches?

A: Yes, the system supports flexible batch sizes. Use the adjustable rotation speed (0-90 RPM) and partial filling to optimize performance for smaller volumes without compromising efficiency.

2. Q: Can it handle corrosive solvents like acids or chlorinated compounds?

A: Absolutely. The stainless-steel framework, PTFE seals, and corrosion-resistant condenser coils are designed to safely process aggressive chemicals, ensuring long-term durability.

3. Q: How often should maintenance be performed?

A: Basic cleaning after each use is critical. Lubricate moving parts every 500 hours, inspect seals monthly, and clean condenser coils quarterly to maintain peak performance.

4. Q: Does it require specialized training to operate?

A: No. The intuitive interface and automated lifting system simplify operation. However, we provide free onboarding webinars and detailed manuals for advanced features.

5. Q: What if the overheating protection is triggered?

A: The system will auto-shutoff and display an error code. Check for blockages in the condenser or excessive flask loading. Our 24/7 support team can remotely diagnose issues if needed.

Product Parameters

Model | RE-1002 | RE-2002 | RE-5002 |

Evaporating Flask(L) | 10 | 20 | 50 |

Receiving Flask(L) | 5 | 10 | 20 |

Rotating Motor(W) | 180 | 250 | |

Rotating Speed(r/min) | 0~120 | 0~90 | |

Water(Oil) Bath Power(W) | 3000 | 5000 | 7000/9000 |

Temperature Control Range | RT~99(250)℃ | ||

Temperature Fluctuation(℃) | ±1 | ||

Evaporation Rate(H2O) | >3L/h | >5L/h | >9L/h |

Condenser | Vertical Double Condenser | ||

Lifting Mode | Water(Oil) Bath Manual Lifting | ||

Lifting Height(mm) | 0~220 | ||

Voltage | 220V/50HZ | 380V/50HZ | |

Sealing Mode | PTFE, Fluoro Rubber Sealing | ||

Model | RE-5002 |

Evaporating Flask(L) | 50 |

Receiving Flask(L) | 20 |

Rotating Motor(W) | 250 |

Rotating Speed(r/min) | 0~90 |

Water(Oil) Bath Power(W) | 7000/9000 |

Temperature Control Range | RT~99(250)℃ |

Temperature Fluctuation(℃) | ±1 |

Evaporation Rate(H2O) | >9L/h |

Condenser | Vertical Double Condenser |

Lifting Mode | Water(Oil) Bath Manual Lifting |

Lifting Height(mm) | 0~220 |

Voltage | 380V/50HZ |

Sealing Mode | PTFE, Fluoro Rubber Sealing |

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China