50 Liter Rotary Evaporator

The Complete Guide to Industrial-Evaporators for Large-Scale Applications

Industrial-Grade Efficiency for Chemical, Pharmaceutical & Research Labs

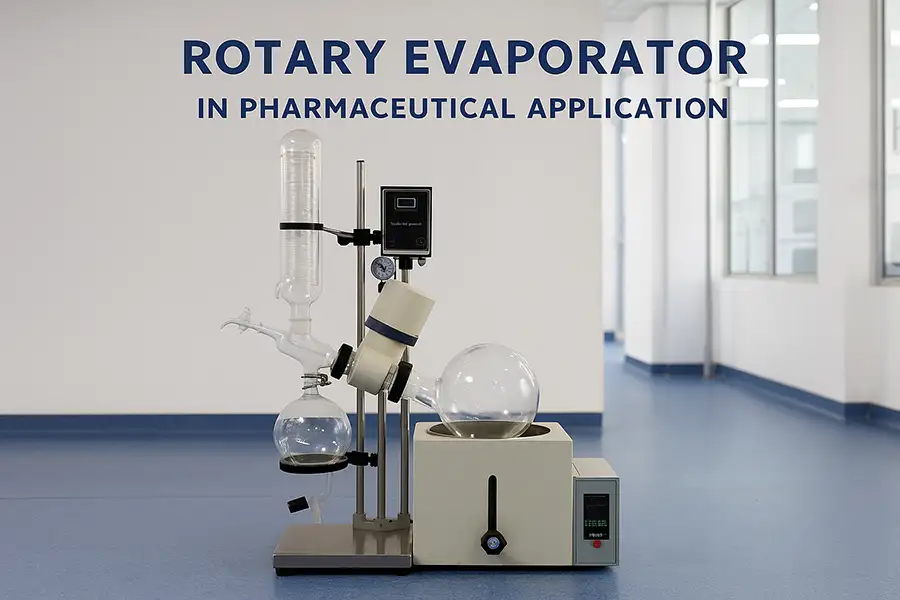

Understanding 50L Rotary Evaporators

Large-scale solvent removal and purification systems

A 50 liter rotary evaporator is an industrial-grade evaporation system designed for efficient solvent removal and purification at large volumes. This high-capacity scientific instrument is essential for applications where batch processing of substantial liquid volumes is required under controlled temperature and pressure conditions.

By combining rotation with reduced pressure distillation, these systems achieve significantly faster evaporation rates than smaller models while maintaining precision control over thermal conditions - critical for sensitive compounds.

Industrial Capacity

Processes 50-liter batches efficiently for large-scale production

Working Principles of Rotary Evaporators

Rotary evaporators work by reducing the pressure inside the evaporation flask, which lowers the boiling point of solvents. This enables evaporation at significantly lower temperatures. The key operational sequence:

Reduced pressure enables solvents to evaporate at much lower temperatures, typically 20-30°C below their standard boiling points. This is critical for heat-sensitive compounds (like many pharmaceuticals and natural extracts) as it prevents thermal degradation and decomposition. Additionally, it increases evaporation efficiency and speeds up the distillation process.

Primary Technical Applications

The industrial 50L rotary evaporator is indispensable in research and commercial processes requiring high-volume solvent processing:

Emerging Applications

Cannabis concentrate refinement for legal markets

Biodiesel purification processes

Wine dealcoholization at commercial scale

Nano-particle synthesis in material science

Industrial solvent recycling initiatives

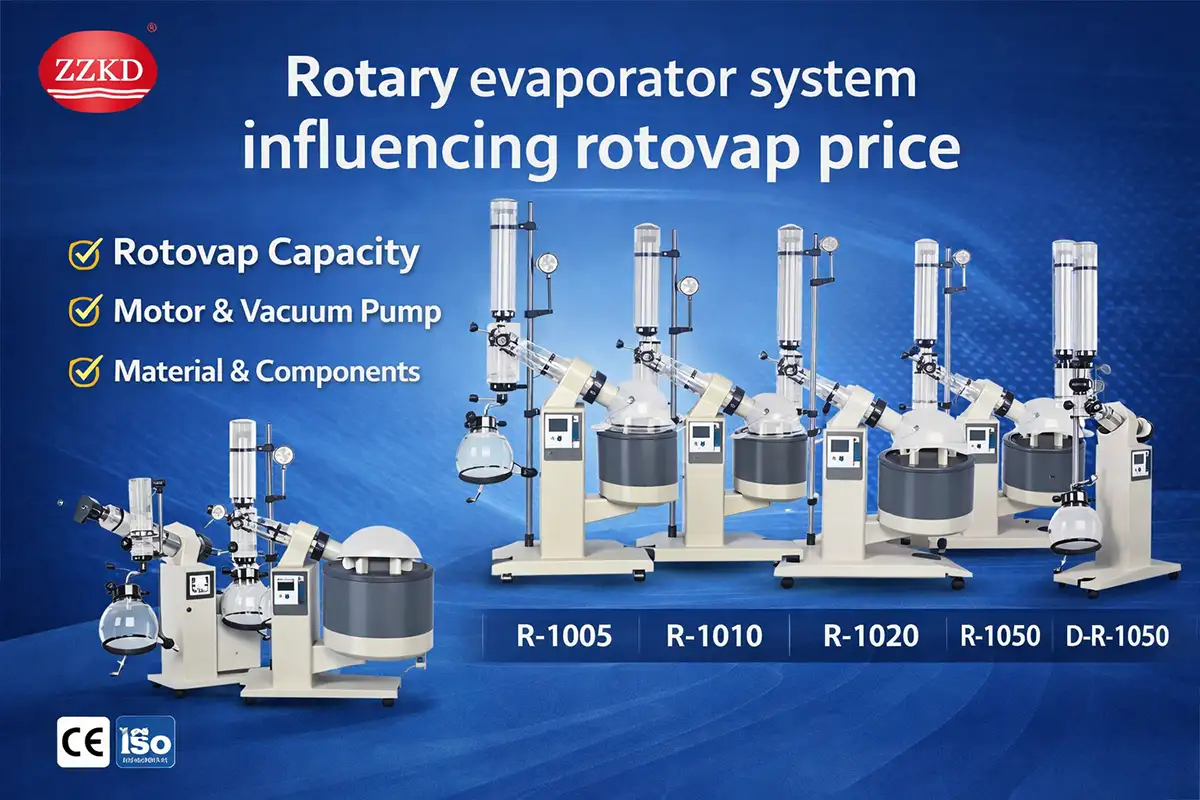

Industrial Capacity Comparison

Selecting the proper evaporator size is critical for efficiency and productivity. Below is a technical comparison of common rotary evaporator sizes:

| Model | Capacity | Max Rotation Speed | Applications | Space Required |

|---|---|---|---|---|

| 2L (RE-201D) | 2 Liters | 280 RPM | Research & Development | Compact Benchtop |

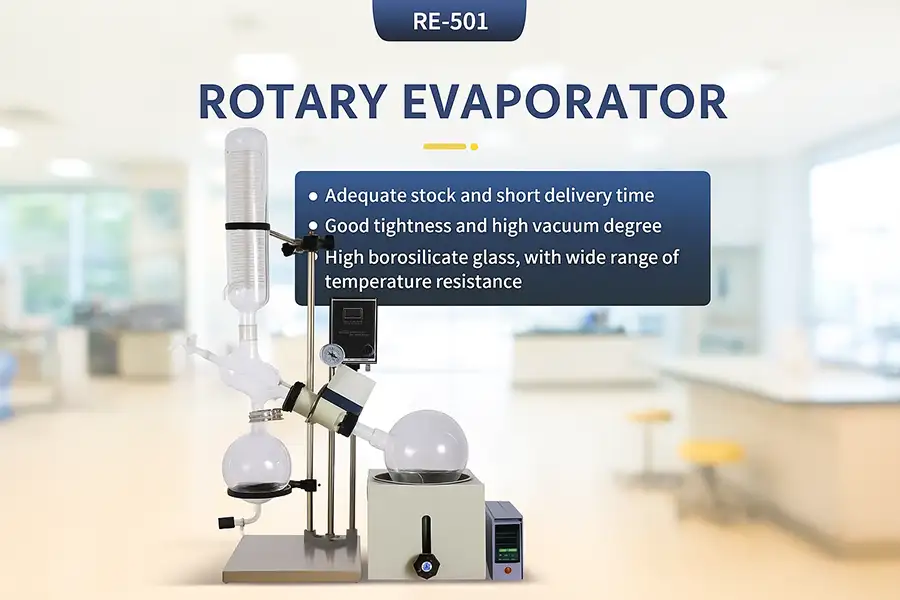

| 5L (RE-501) | 5 Liters | 200 RPM | Pilot Scale Testing | Medium Lab Space |

| 50L (RE-1050) | 50 Liters | 120 RPM | Industrial Production | Dedicated Floor Area |

For small research laboratories processing volumes under 5 liters per batch, a 50L rotary evaporator typically isn't cost-effective. The significant capital expense, maintenance complexity, and space requirements make smaller models (1-5L) more suitable. However, for specialized facilities that require occasional large-volume processing, modular expansions to existing smaller systems or shared equipment facilities provide practical alternatives.

Key Advantages of 50L Systems

Scaled Efficiency

Processes equivalent of 10x 5L batches simultaneously, reducing processing time and labor costs

Solvent Recovery

Recovers over 95% of solvents for reuse, achieving major cost reduction in industrial operations

Material Compatibility

Constructed with chemically resistant borosilicate glass and PTFE components for handling aggressive solvents

Automation Compatibility

Integration with PLC systems for unattended operation and GMP compliance recording

Safety Systems

Built-in safety protocols including auto shutdown for pressure deviations, temperature limits, and motor overloads

Operational Continuity

Designed for continuous operation cycles to maintain production schedules

Automated rotary evaporators significantly enhance laboratory and industrial safety through several mechanisms: reducing operator exposure to solvents and vapors; preventing accidents through precise control of critical parameters; implementing automatic emergency shutdown protocols; and maintaining digital audit trails for regulatory compliance. These systems minimize human error - a leading cause of laboratory accidents according to OSHA studies.

Industrial & Research Significance

The importance of industrial-scale evaporation technology continues to grow in parallel with demands in pharmaceutical manufacturing and specialty chemical production. According to industry analysis, the global rotary evaporator market is projected to reach $1.2 billion by 2028, driven by:

Pharmaceutical R&D expansion with biologics and complex molecules

Increased botanical extraction for nutraceuticals worldwide

Green chemistry initiatives requiring solvent recovery

Automation integration reducing operational costs by 40%

Demand for energy-efficient large-scale systems

Growth in cannabis-derived product manufacturing

Conclusions & Specifications

The 50 liter rotary evaporator represents industrial-scale efficiency for solvent removal and purification operations. With processing capacities unattainable by smaller benchtop units, these systems are indispensable assets for any production environment requiring large-volume solvent processing with precision temperature control.

When considering implementation, evaluate required batch sizes against equipment costs and space requirements. For most GMP pharmaceutical production and large-scale extraction facilities, the significant productivity gains justify the capital investment.

RE-1050 Key Specs

Max Capacity: 50L borosilicate flask

Rotation: 10-120 RPM digital control

Temperature Range: 20°C - 180°C

Min Vacuum: ≤ 5 mbar

Safety: Class I compliant

Dimensions: 180 x 90 x 210 cm

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

How Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read MoreWhat Does a Rotary Evaporator Do?

Discover what a rotary evaporator does, how it works, and why it is essential in laboratories and chemical industries. Learn about different models like 2L, 5...

Read More