Rotovap distillation is a widely used technique in laboratories and chemical industries for the efficient removal of solvents from samples. The term "rotovap" refers to a rotary evaporator, a device that uses controlled heating, reduced pressure, and rotation to separate solvents from desired compounds.

This method is essential in organic chemistry, pharmaceuticals, food processing, and environmental testing for its efficiency and ability to handle heat-sensitive compounds.

Efficient Solvent Removal

Rotovap systems dramatically reduce solvent evaporation time through vacuum and rotation.

Heat-Sensitive Processing

Precisely controlled temperature settings preserve delicate compounds.

Solvent Recovery

Advanced systems reclaim up to 95% of solvents with purity for reuse.

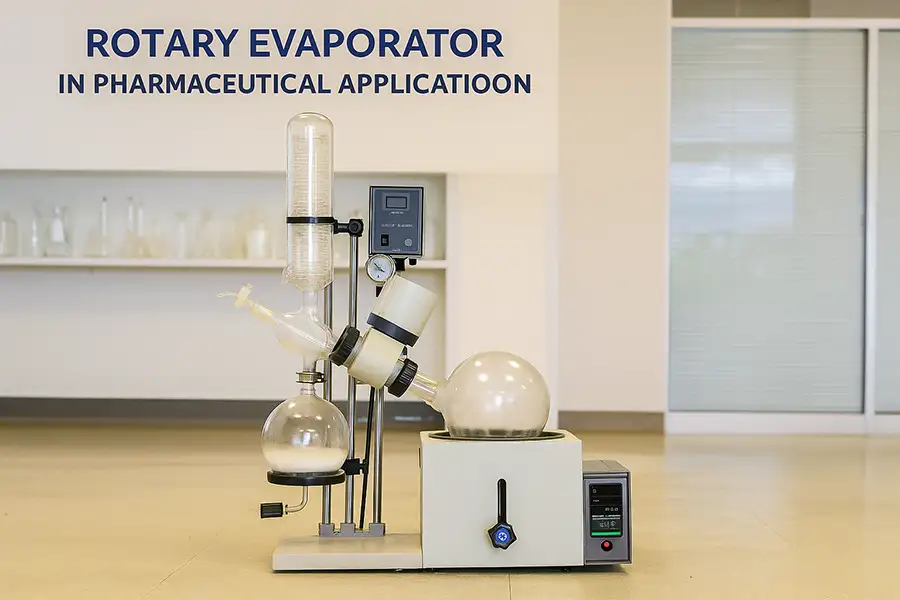

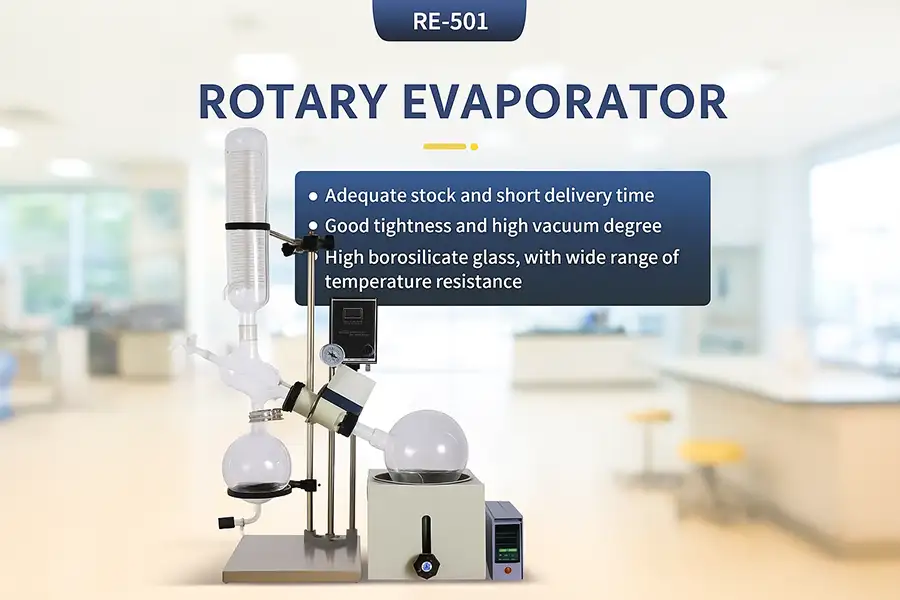

Rotary evaporator in a pharmaceutical laboratory environment

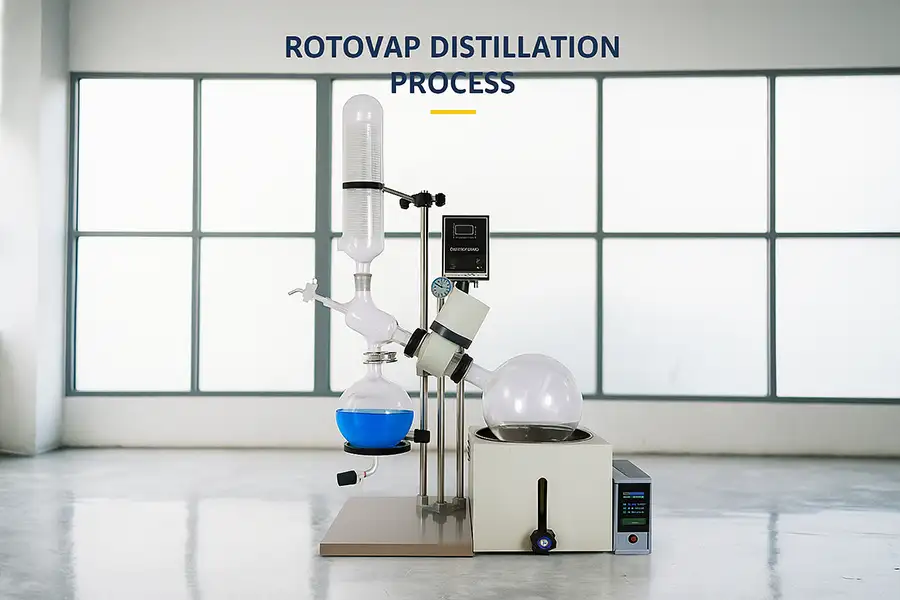

What is Rotovap Distillation?

Rotovap distillation involves placing a liquid sample in a rotating flask, heating it gently, and applying vacuum pressure to lower the boiling point of the solvent. The solvent evaporates and is condensed in a separate collection flask. This process allows for the recovery of both the solvent and the concentrated compound.

The rotation creates a thin film of liquid that greatly increases the surface area for evaporation, while the vacuum reduces the boiling point, enabling efficient solvent removal at low temperatures.

Applications of Rotary Evaporators

Rotary evaporators serve as versatile tools across multiple industries:

Pharmaceuticals: Extraction of active ingredients without structural damage

Food Technology: Concentration of natural flavors and removal of processing solvents

Environmental Analysis: Isolation of pollutants from water and soil samples

Essential Oils: Gentle extraction of aromatic compounds

Cannabis Industry: THC extraction and purification processes

Rotovap used in food chemistry for flavor concentration

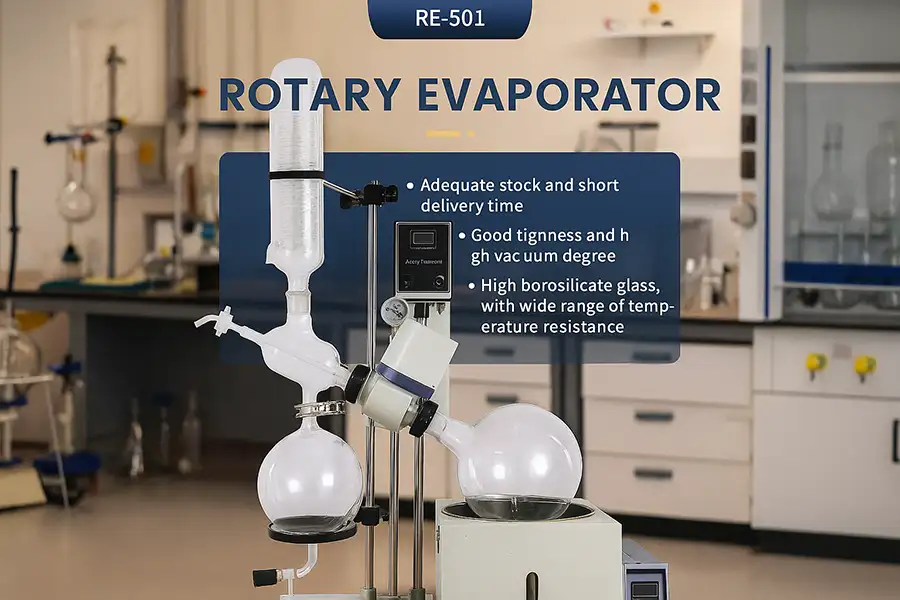

Common Rotary Evaporator Models

Rotary evaporators are available in various sizes depending on the scale of operation:

| Model | Capacity | Applications | Link |

|---|---|---|---|

| RE-201D Rotary Evaporator | 2L | Small experiments, academic labs | View Product |

| RE-501 Rotary Evaporator | 5L | Standard research labs, pilot plants | View Product |

| RE-1002 Rotary Evaporator | 10L | Production environments, industrial use | View Product |

| Mini Rotary Evaporator | 0.5-1L | Education, small-scale tests | View Product |

Industry Impact and Developments

According to studies, rotary evaporation technology continues to evolve with significant developments:

Market Growth

The lab rotovap market is projected to reach $800 million by 2027

Automation Revolution

Modern units feature automated controls and remote operation capabilities

Sustainability Focus

New designs significantly reduce energy consumption and solvent waste

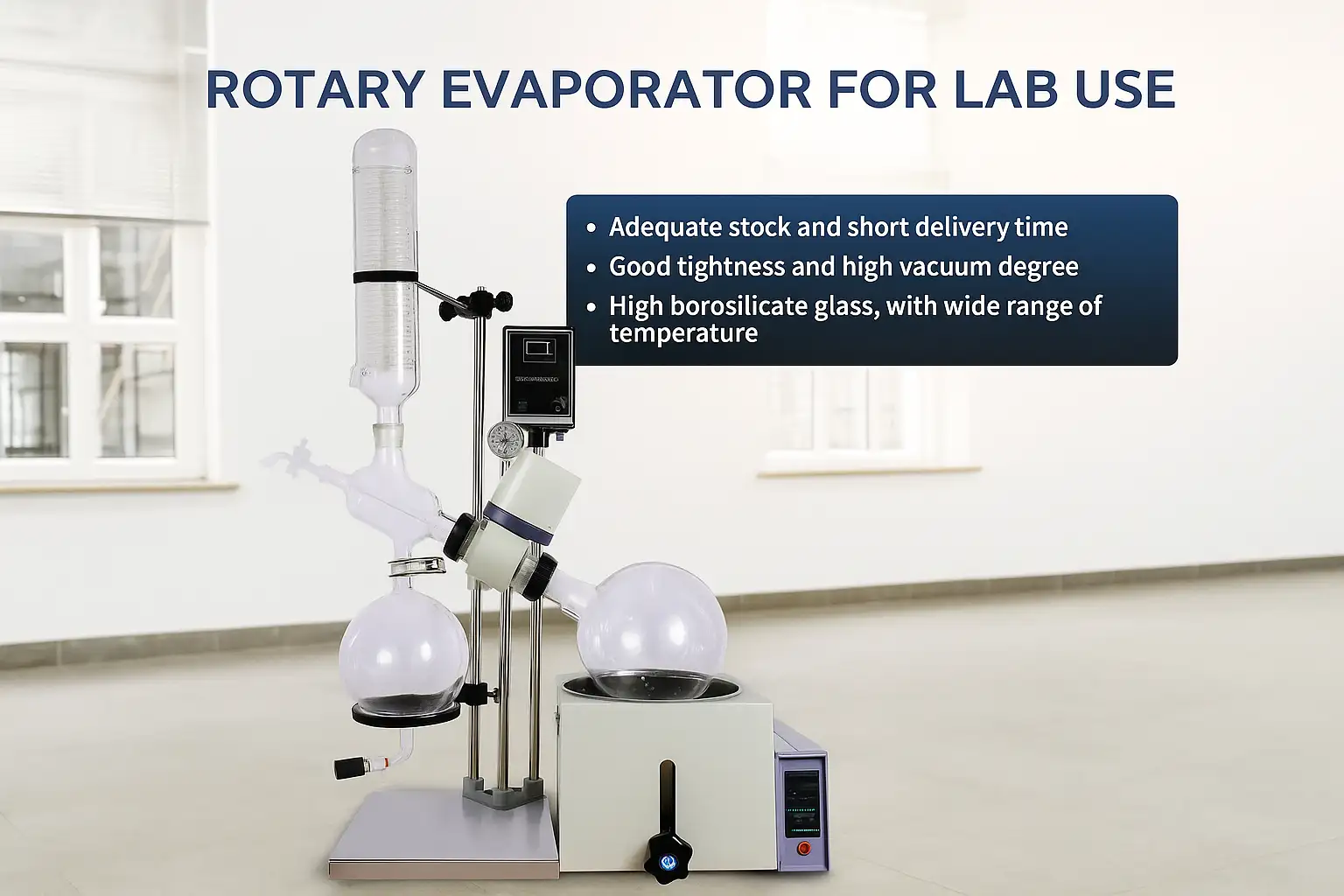

Modern automated rotovap system with safety features

Key Advantages of Rotovap Distillation

Conclusion

Rotovap distillation continues to be a cornerstone technique in modern laboratories. Whether you require a 5L system for development work or a 50L industrial rotary evaporator for commercial production, today's models offer unprecedented efficiency, safety, and control.

Technology Outlook

The next generation of rotary evaporators will incorporate IoT technology for remote monitoring, AI optimization for solvent recovery rates, and eco-friendly designs that minimize environmental impact.