How Do Rotary Evaporators Work?

Rotary evaporators (often called “rotavaps”) are one of the simplest ways to remove solvents gently and quickly. This guide explains the working principle in plain English, what problems a rotary evaporator solves, and how to choose the right size—without drowning in jargon.

Understand vacuum + rotation + condensation

Know which parameters actually matter

Pick 2L / 5L / 10L / 20L / 50L models confidently

Quick introduction

What a rotary evaporator helps you do (and why people buy one)

I work with rotary evaporator selection and application for labs that need reliable solvent removal—chemistry teaching labs, R&D teams, extraction workflows, and scale-up pilots. The problem is almost always the same: a process needs to concentrate a solution or recover a solvent, but boiling it in an open beaker is too slow, too hot, and too risky.

A rotary evaporator solves that by lowering the boiling point (using vacuum), spreading the liquid into a thin film (by rotation), and immediately condensing the vapor into a receiving flask (using a condenser). The result: faster evaporation at gentler temperatures, with better control and higher solvent recovery.

How do rotary evaporators work? (The simple step-by-step)

The working principle is straightforward. A rotary evaporator is basically a controlled “boil-and-catch” system: it evaporates solvent from a rotating flask and captures that solvent in another flask—while keeping temperatures lower than normal boiling.

1) Gentle heating

The flask sits in a water or oil bath. The bath provides stable heat, typically from room temperature up to high setpoints depending on the model.

2) Vacuum lowers boiling point

A vacuum pump reduces pressure, so the solvent boils at a lower temperature. That protects heat-sensitive compounds.

3) Rotation creates a thin film

Rotation (often 0–120 rpm on many units) spreads liquid as a thin layer, increasing surface area and speeding evaporation.

4) Condensation & recovery

Vapor moves into a cooled condenser, becomes liquid again, and drips into a receiving flask for easy solvent recovery.

Why vacuum + rotation beat “just heating”

Heating alone can damage compounds and still take a long time. Vacuum and rotation change the physics in your favor:

Vacuum reduces the boiling point, so evaporation happens at lower temperatures.

Rotation reduces bumping and forms a thin film for faster mass transfer.

Closed vapor path improves safety and keeps the lab environment cleaner.

Key parameters that matter (with real examples)

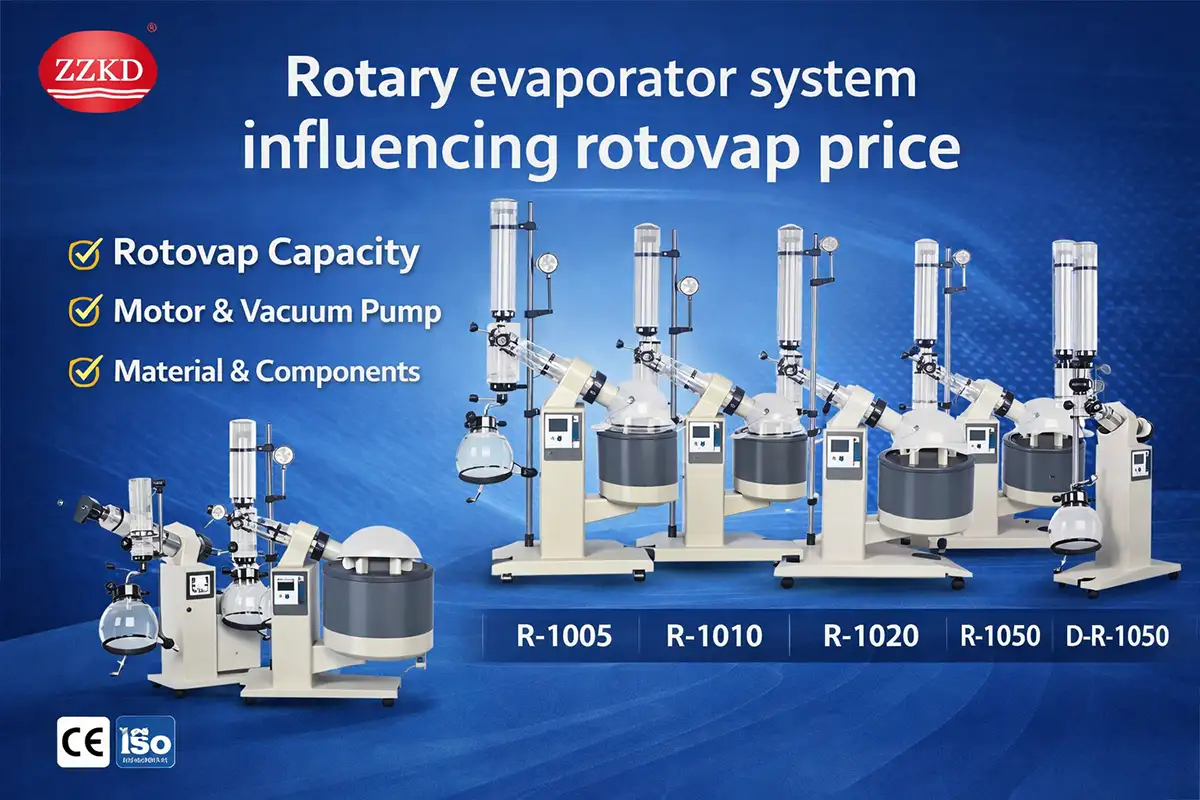

Buyers often ask about “power” or “maximum temperature,” but the most useful specs relate to capacity, evaporation rate, vacuum capability, and control stability. Below are representative specs from common rotary evaporator configurations (2–5 L and 10–50 L classes).

| Model Class | Evaporating Flask | Receiving Flask | Speed Range | Typical Evaporation Rate (H₂O) | Max Vacuum Degree | Notes |

|---|---|---|---|---|---|---|

| Bench (RE-201D/301/501) | 2–5 L | 1–3 L | 0–120 rpm | >1 to >1.5 L/h | <133 Pa (≈1.33 mbar) | Digital bath control; PTFE/fluoro-rubber sealing |

| Mid/Large (RE-1002/2002/5002) | 10 / 20 / 50 L | 5 / 10 / 20 L | 0–120 rpm (10L), 0–90 rpm (20–50L) | >3 / >5 / >9 L/h | High vacuum system dependent | Vertical double condenser; manual bath lifting |

Notice how the larger systems advertise higher evaporation rates, but also tend to run at lower maximum rpm—because volume, viscosity, and mechanical stability become more important at scale.

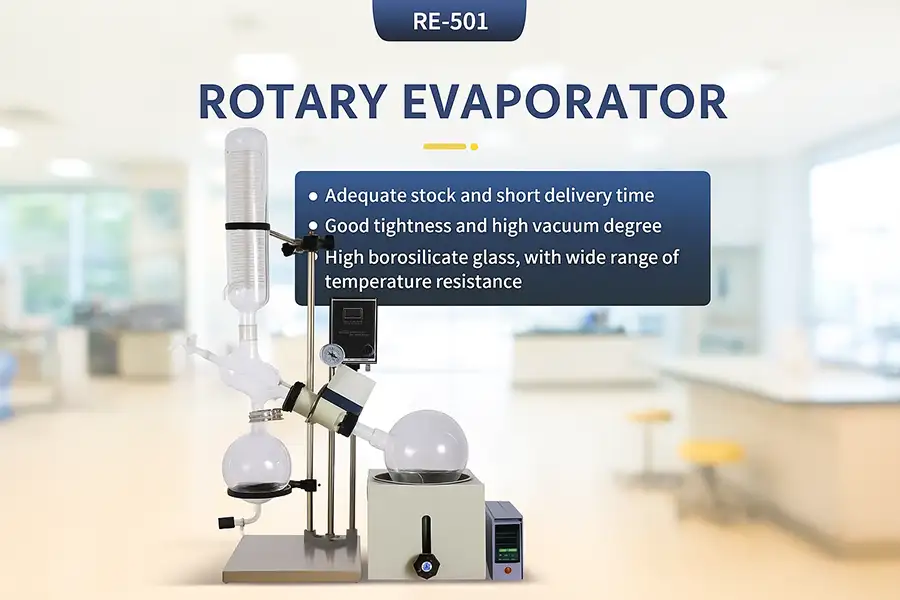

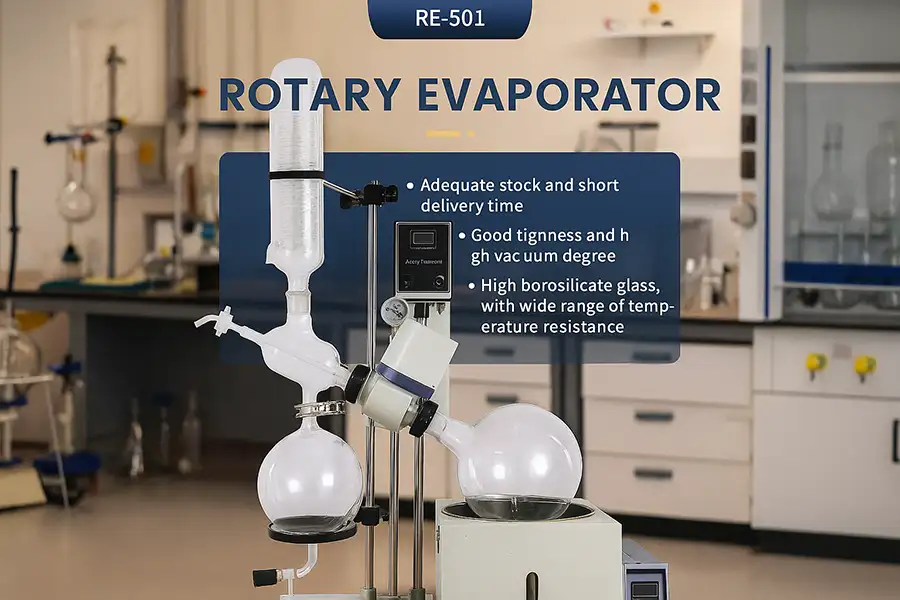

For product pages tied to these capacities, these internal links may help:2L rotary evaporator (RE-201D),5L rotary evaporator (RE-501), and10L rotary evaporator (RE-1002).

How to choose the right rotary evaporator size (2L to 50L)

Most people don’t need the biggest unit—they need the unit that matches batch size and time expectations. A practical rule: choose an evaporating flask that is at least 2–3× the working volume to reduce bumping and allow safe film formation.

2L–5L: daily lab work

Great for teaching labs and R&D where batches are smaller but frequent, and flexible solvent changes are common.

10L–20L: pilot and prep

Useful when throughput matters and solvent recovery is a routine operation. Often paired with stronger vacuum and better chillers.

50L: production-style concentration

Designed for higher daily volumes. Pay extra attention to condenser capacity, vacuum stability, and safe lifting/handling.

Common user questions (and the fixes)

1) “Why does the sample bump or foam?”

Bumping usually happens when pressure drops too quickly or the bath is too hot. Reduce vacuum gradually, increase rotation in steps, and avoid filling the flask too high. Anti-bumping granules can help in some cases, but careful vacuum control is the real solution.

2) “Why is solvent recovery low?”

Common causes include insufficient condenser cooling, poor vacuum seals, or an undersized condenser for the evaporation rate. Verify PTFE sealing integrity, check connections, and ensure the condenser has adequate coolant flow and temperature.

3) “What temperatures are safe?”

Temperature depends on solvent, vacuum level, and sample sensitivity. The point of rotovapping is to use lower bath temperatures while still achieving boiling under vacuum. Start low, then increase only if evaporation is stable and bump-free.

Summary: the easiest way to remember how rotary evaporators work

If the question is “how do rotary evaporators work,” the answer is:vacuum lowers the boiling point, rotation spreads the liquid into a thin film, and the condenser captures vapor as liquid. That combination removes solvent faster, at gentler temperatures, with improved recovery and cleaner operation.

For choosing a model, focus on flask size, expected evaporation rate, vacuum stability, and condenser capacity—then match those to the daily workflow.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

Rotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read MoreComplete Guide to 50L Rotary Evaporators

Complete guide to 50 liter rotary evaporators - working principles, applications, and industrial significance...

Read MoreWhat Does a Rotary Evaporator Do?

Discover what a rotary evaporator does, how it works, and why it is essential in laboratories and chemical industries. Learn about different models like 2L, 5...

Read More