How can you choose the perfect rotary evaporator for your laboratory or production needs?

Struggling with inefficient solvent removal? Need a reliable way to concentrate your samples? Finding the right equipment can be tough. This often leads to wasted time and resources.

Choosing the right rotary evaporator involves matching its capacity, features, and vacuum system to your specific applications, ensuring efficient and safe solvent recovery. We'll guide you through the key considerations.

As a manufacturer with over 16 years of experience exporting these machines worldwide, I've seen firsthand how the right rotary evaporator machine can transform a lab's workflow. It's not just about buying a piece of equipment; it's about investing in efficiency and reliability for your crucial work, whether it's for research, development, or small-scale production. Let's explore how to make the best choice.

What exactly does a rotary evaporator do for my lab work?

Are you spending too much time on solvent evaporation? Finding traditional methods slow and sometimes damaging to your samples? This can really slow down your research or production.

A rotary evaporator efficiently removes solvents from samples by using gentle heat, reduced pressure, and rotation. This speeds up evaporation, protects sensitive compounds, and allows for solvent recovery.

A rotary evaporator, often called a "rotovap," is a very common tool in chemical laboratories. I remember when we first started exporting, many clients were amazed by how much it improved their processes. The basic idea is simple but very effective. You have a flask with your sample, and this flask rotates in a heated water or oil bath. This rotation increases the surface area of the liquid and helps to distribute the heat evenly.

Key Working Principles:

Reduced Pressure: A vacuum pump is connected to the system. By lowering the pressure, the boiling point of the solvent also lowers. This means you can evaporate solvents at lower temperatures, which is great for heat-sensitive materials.

Rotation: The rotating flask spreads the sample into a thin film on the inner surface. This greatly increases the evaporation rate and prevents bumping or violent boiling.

Controlled Heating: The heating bath provides gentle and controlled heat to the sample. You can adjust the temperature based on the solvent you are using.

Condensation: The evaporated solvent vapor travels into a condenser. The condenser is cooled (usually by a chiller or tap water), causing the vapor to turn back into a liquid. This liquid solvent is then collected in a separate flask, allowing for recovery and reuse if needed.

This process is much faster and more gentle than, for example, evaporating on a hot plate or using a distillation setup for simple solvent removal. It's essential for tasks like concentrating solutions, purifying solvents, or drying extracts. We make sure our designs maximize these principles for top performance.

How do I pick the right size rotary evaporator for my needs?

Worried about buying a unit that's too small for your batches, or too large and wasteful for your typical sample sizes? Choosing the wrong capacity can cause big problems.

Select a rotary evaporator size based on your typical sample volume and processing frequency. Consider flask sizes from 1L for small research to 50L or more for pilot or production scales.

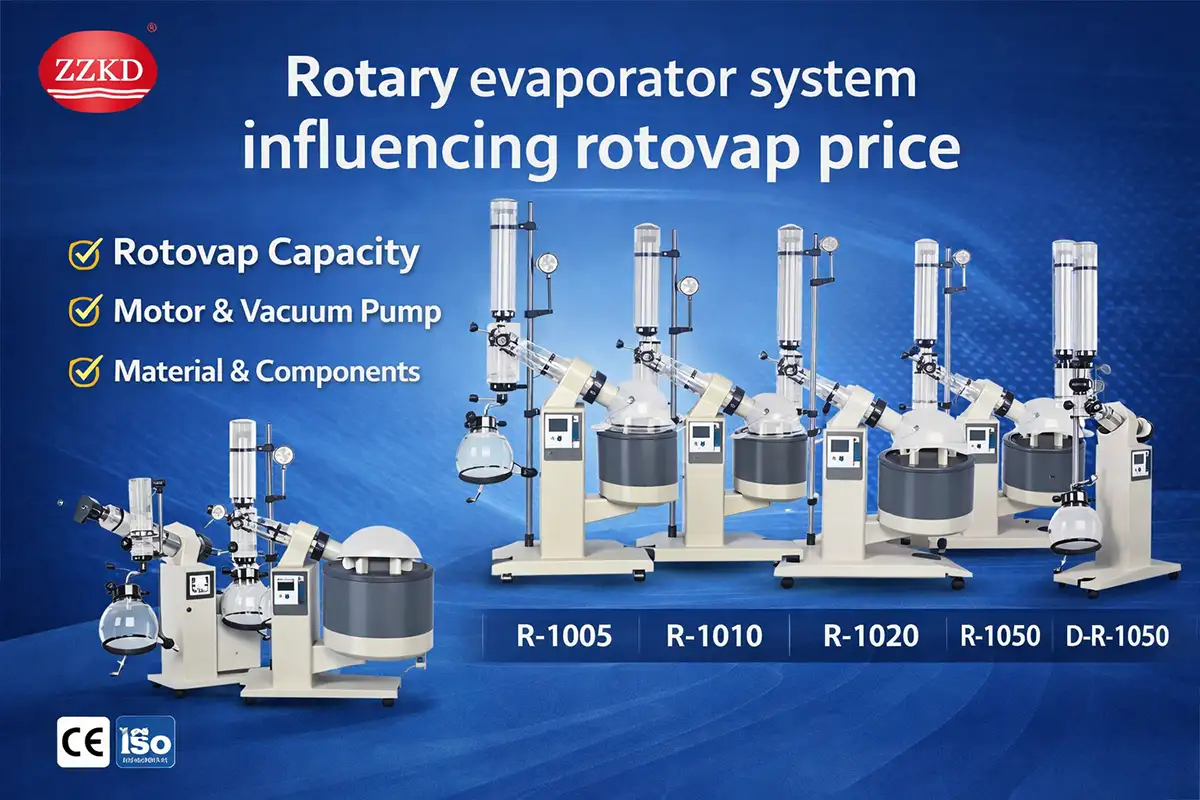

The size of the evaporating flask is the main way we categorize rotary evaporators. It directly tells you the maximum volume of sample you can process at one time (though you usually fill the flask to about half its capacity for best results). We manufacture a wide range, from small rotary evaporator models perfect for academic labs, to much larger units for industrial applications.

Common Sizes and Their Uses:

| Flask Size | Typical Application | Considerations |

|---|---|---|

| 1L - 2L rotary evaporator | Basic research, teaching labs, small sample preparation | Compact, good for limited bench space, lower throughput. Our RE-201D is a popular choice here. |

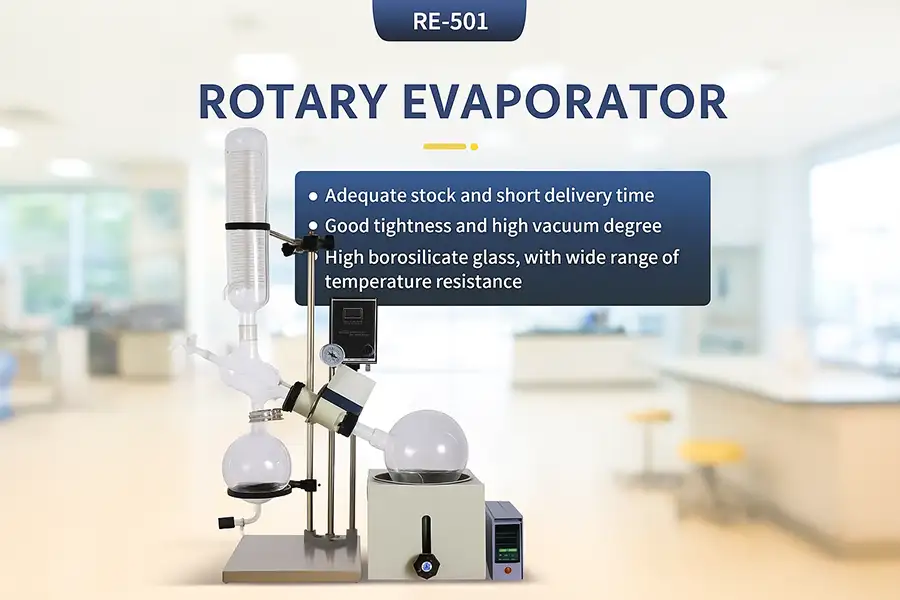

| 5L rotary evaporator | R&D labs, process development, moderate batch sizes | Good balance of capacity and footprint. The RE-501 is a workhorse for many of our clients. |

| 10L rotary evaporator - 20L rotary evaporator | Pilot scale, small production runs, larger research projects | Requires more space, often needs more powerful vacuum and chilling. |

| 50L rotary evaporator and larger | Industrial production, large batch processing | Significant investment, requires dedicated space and infrastructure. We also offer large scale rotary evaporator options. |

Think about your current and future needs. If you are processing many small samples, a smaller unit might be fine. But if your sample volumes are increasing, or you plan to scale up, investing in a slightly larger model could save you time and effort in the long run. I always advise customers to consider their growth plans. It’s often more cost-effective to get a slightly larger unit than to buy a second one later.

What key features make a rotary evaporator good and reliable?

Confused by all the different features and technical specifications? Unsure what really matters for daily, trouble-free operation? It's easy to get lost in the details.

Look for precise temperature control, stable rotation speed, a durable sealing system, quality glassware, and user-friendly controls. Safety features like over-temperature protection are also crucial.

After years of manufacturing and getting feedback from users in 87 countries, we’ve learned what makes a laboratory rotary evaporator truly reliable. It's not just one thing, but a combination of good design and quality components.

Important Features to Check:

Sealing System: This is critical for maintaining vacuum. We use high-quality PTFE and other resistant materials to ensure a long-lasting, tight seal even with aggressive solvents. A poor seal means poor performance.

Lift Mechanism: Whether manual or motorized, the lift should be smooth and allow easy positioning of the flask in the bath. Motorized lifts add convenience and safety, especially for larger flasks. Our rotary evaporator manual lift models are very robust, while our automatic lifts are a popular upgrade.

Rotation Control: A stable and adjustable rotation speed (usually 0-200 RPM or more) is important for optimizing evaporation. The motor should be quiet and durable.

Temperature Control: The heating bath needs precise temperature control. Digital displays and PID controllers are standard on good units. Over-temperature protection is a vital safety feature.

Glassware Quality: Borosilicate glass 3.3 is the standard due to its chemical resistance and thermal shock stability. Check for well-made joints and no internal stresses in the glass.

Ease of Use: Intuitive controls, clear displays, and easy assembly/disassembly of glassware make daily operation much smoother.

Certifications: Look for CE and ISO certifications. These show that the manufacturer follows international quality and safety standards. We are proud to have these for our equipment.

I remember a client from a pharmaceutical company who initially bought a cheaper model from another supplier. They had constant issues with vacuum leaks and inconsistent heating. After switching to one of our units, they reported a significant improvement in their process consistency and a reduction in downtime. It really highlighted how important these features are for serious lab work.

Are the vacuum pump and chiller really that important for my setup?

Thinking you can cut costs by using an old vacuum pump or just tap water for cooling? This might seem like a saving, but it can severely impact your evaporator's performance.

Yes, a suitable vacuum pump and an efficient chiller (or cooling system) are essential for optimal rotary evaporator performance, ensuring low boiling points and effective solvent condensation.

A rotary evaporator doesn't work in isolation. The vacuum pump and the cooling system for the condenser are its critical partners. Neglecting these can lead to slow evaporation, poor solvent recovery, and even sample degradation. I always tell my customers that the rotovap is only as good as its support system.

Why the Vacuum Pump Matters:

Lowering Boiling Points: The primary role of the vacuum pump is to reduce the pressure inside the system. This directly lowers the boiling point of your solvent. For example, water boils at 100°C at atmospheric pressure, but at about 46°C under a vacuum of 100 mbar. This is crucial for temperature-sensitive compounds.

Choosing the Right Pump: You need a pump that can achieve the necessary vacuum level for your solvents and is chemically resistant. Diaphragm pumps are common for rotovaps because they are oil-free and offer good resistance. The pump's flow rate also matters, especially for larger systems.

Why the Chiller/Cooling System Matters:

Efficient Condensation: The condenser needs to be cold enough to effectively turn the solvent vapor back into a liquid. If the condenser is too warm, solvent vapor can escape through the vacuum pump, leading to poor recovery and potential release of harmful fumes.

Chillers vs. Tap Water: While tap water can sometimes be used for cooling, it's often not ideal. Water temperature can vary, and usage can be high. A recirculating chiller provides consistent, low temperatures (e.g., 5°C or lower) and saves water. For many organic solvents, you need coolant temperatures significantly below room temperature for good condensation. We often bundle chillers with our rotary evaporators because they are so important for performance.

Consider the solvents you'll be using. Solvents with very low boiling points (like dichloromethane or diethyl ether) require a deeper vacuum and more efficient cooling to condense properly. Investing in a good pump and chiller matched to your rotary evaporator and applications will pay off in terms of efficiency, solvent recovery, and safety.

What should I know about the glassware and safety of a rotary evaporator?

Concerned about handling glassware under vacuum and heat? Worried about potential accidents or solvent exposure in your lab? Safety should always be a top priority.

Always use high-quality borosilicate glassware designed for vacuum. Ensure all connections are secure. Utilize safety features like protective shields, over-temperature cutoffs, and proper ventilation.

Working with rotary evaporators involves vacuum, heat, and often flammable or hazardous solvents. So, understanding the glassware and safety aspects is extremely important. We design our equipment with safety in mind, but user awareness is also key.

Glassware Integrity:

Material: As I mentioned, borosilicate glass 3.3 is the standard. It can handle thermal stress and is very resistant to most chemicals.

Inspection: Always inspect glassware for cracks, chips, or scratches before use. Even small flaws can become weak points under vacuum and heat, potentially leading to implosion or breakage. We ensure our glassware is manufactured to tight tolerances.

Proper Assembly: Ensure all glass joints are clean and properly greased (if using ground glass joints) for a good vacuum seal. Use Keck clips or other joint clips to secure connections, but don't force them.

Flask Capacity: Never overfill the evaporating flask. A good rule of thumb is to fill it to no more than half its volume to prevent bumping and ensure efficient evaporation.

Safety Features and Practices:

Safety Shield: Many models come with a transparent safety shield around the heating bath or the evaporating flask. This protects the user in case of splashes or flask breakage.

Over-Temperature Protection: The heating bath should have a system to prevent overheating, which could damage your sample or create a fire hazard.

Smooth Lift: A reliable lift mechanism (manual or motorized) allows you to quickly remove the flask from the hot bath in an emergency.

Ventilation: Always operate a rotary evaporator in a well-ventilated area or under a fume hood, especially when working with volatile or toxic solvents.

Personal Protective Equipment (PPE): Wear safety glasses, gloves, and a lab coat.

Emergency Stop: Know where the power switch or emergency stop button is located.

I recall an incident a trainee in our R&D lab shared from their university days. They were using an old rotovap without a proper shield, and a flask imploded due to a small crack. Luckily, no one was seriously hurt, but it was a stark reminder of why these safety precautions and equipment features are so vital. That's why we emphasize robust construction and safety checks in our own manufacturing.

Why should I consider getting my rotary evaporator from a direct manufacturer like you?

Tired of dealing with middlemen and unclear support? Want direct access to expertise and a reliable supply chain for your laboratory equipment? Choosing your supplier is a big decision.

Buying directly from an experienced manufacturer like us, Zhengzhou Keda (ZZKD), ensures quality control, competitive pricing, customized solutions, and dedicated after-sales support from experts who know the equipment inside out.

Choosing where to buy your laboratory equipment is just as important as choosing the equipment itself. As a company that has specialized in R&D, production, and export of laboratory instruments for over 16 years, we believe there are strong advantages to working directly with a manufacturer like ZZKD.

Benefits of Partnering with ZZKD:

Direct-from-Factory Pricing: By eliminating intermediaries, we can offer more competitive pricing without compromising on quality. This means better value for your investment.

Quality Assurance: We control the entire production process, from raw materials to final assembly and testing. Our ISO9001 and CE certifications are a testament to our commitment to international quality standards. I personally oversee many quality checks because our reputation depends on it.

Deep Product Knowledge: When you talk to us, you're talking to people who design, build, and troubleshoot these machines daily. Over 50% of our engineers are fluent in English, ready to provide expert advice.

Customization: Need a specific modification or a complete system tailored to your unique process? As manufacturers, we have the flexibility to offer customized solutions that a reseller often cannot.

After-Sales Support: This is crucial. We were the first manufacturer in China to establish a 24/7 after-sales support team. We offer a one-year warranty with free maintenance and lifetime cost-price service. We want to ensure your equipment runs smoothly for years. I've spoken to many customers who value this ongoing support highly.

Experience: With 16 years of continuous international export experience to 87 countries, we understand the needs of global customers and the logistics of getting equipment to you safely and efficiently.

We've built our business on "Made in China + International Quality." It's not just a slogan; it's our operational philosophy. We invite technical exchange and factory visits because we are proud of our work and believe in transparency. When you choose ZZKD, you're not just buying a rotary evaporator; you're gaining a reliable partner for your laboratory's success.

Choosing the right rotary evaporator means matching size, features, and support to your lab's needs. This ensures efficient, safe, and reliable solvent processing for your important work.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

What Is a Rotary Evaporator? Beginner-Friendly Guide to Rotary Evaporation

Learn what a rotary evaporator is, how it works, and how it solves common solvent removal problems in laboratories and production. Clear, beginner-friendly ex...

Read MoreHow Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read More