What Really Determines the Cost of a Rotary Evaporator?

Struggling with lab budgets? Rotary evaporator costs seem complex? Finding the right one without overspending is often tough for many labs I talk to.

The cost of a rotary evaporator is mainly set by its size, features like vacuum control and lift type, and the materials used. Brand reputation and included accessories also play a big role in the final price you pay for your equipment.

As a manufacturer with over 16 years of experience exporting laboratory instruments, I've seen how these factors come together. We always aim to provide clear information to help you choose wisely. Let's look closer at what drives the price so you can make a good decision for your lab or facility.

What Key Factors Influence a Rotary Evaporator's Price Tag?

Confused by varying rotary evaporator prices? Unsure what justifies a higher cost? It is hard to compare different models side-by-side sometimes.

Key factors include capacity (flask size), motor type (manual/auto lift), glass quality, vacuum controller sophistication, and temperature range. These directly impact performance and durability, and so they affect the price.

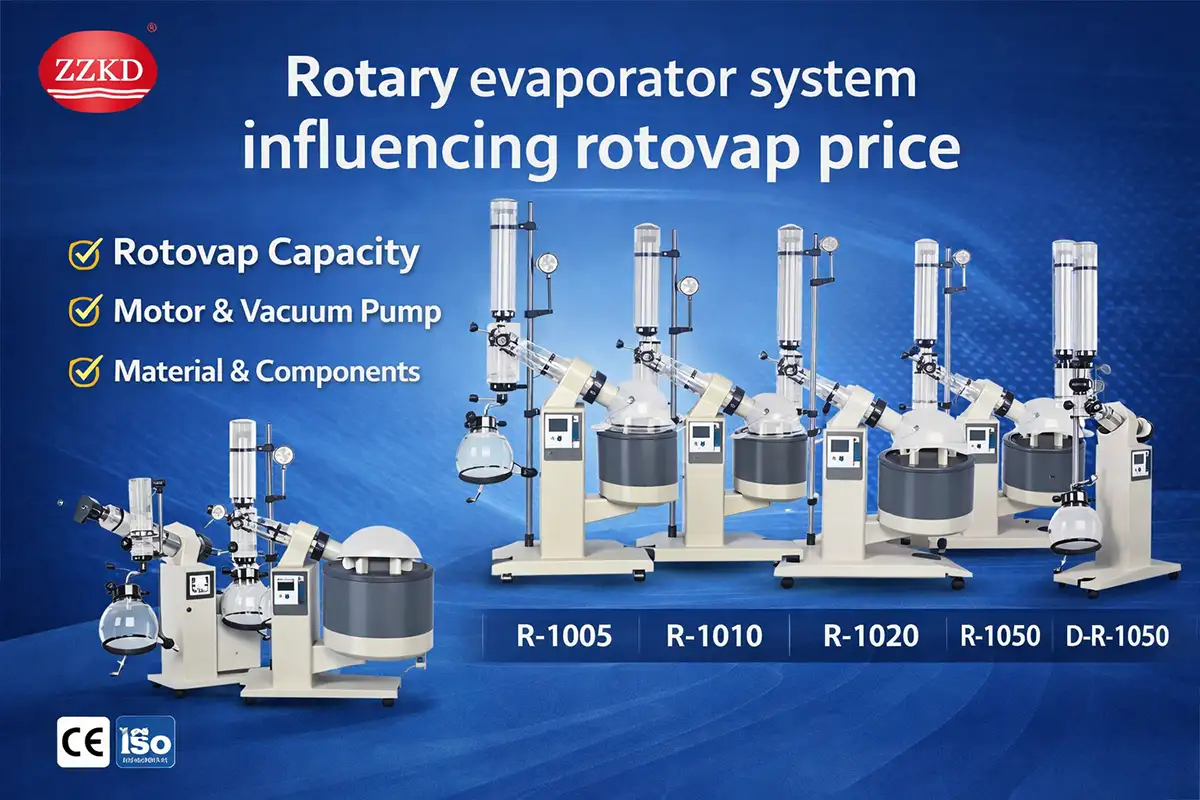

When we talk about the cost of a laboratory rotary evaporator, several components are very important. I often tell my clients to think about their daily work. For example, the flask size, or capacity, is a primary driver. A small 2L rotary evaporator will naturally cost less than a larger 10L rotary evaporator or even a large scale rotary evaporator designed for pilot production. This is because more material and more robust engineering are needed for bigger units.

Lift Mechanism and Glassware

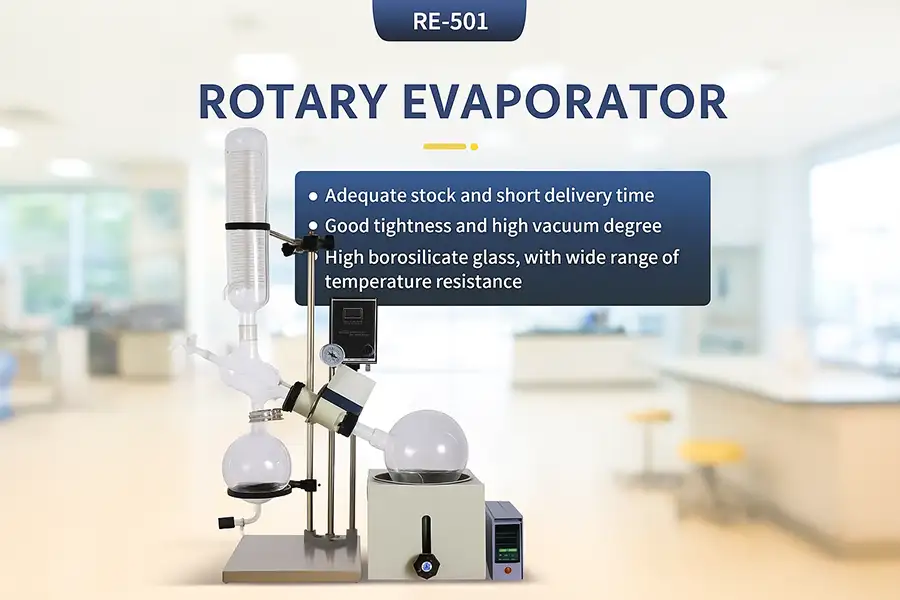

The lift mechanism, whether it's a manual lift or a motorized automatic lift, also impacts price. Motorized lifts offer more convenience and safety, especially for heavier flasks, but they add to the cost. The quality of glassware is another big point. We use high borosilicate glass 3.3 for its chemical resistance and ability to handle thermal stress. Some applications might need coated safety glassware, which adds a bit more to the price but offers extra protection. Seals are also vital; PTFE seals are standard for us due to their excellent chemical compatibility, ensuring a longer lifespan for the equipment.

Control and Safety

Then there's the vacuum system and temperature control. Precise vacuum control is crucial for efficient evaporation, especially for sensitive compounds. Integrated controllers or high-quality standalone pumps contribute to the cost. The heating bath's temperature accuracy and range are also key. Finally, safety features and certifications like CE, which all our export models have, ensure the equipment meets international standards, and this quality assurance is part of the value and cost. I remember one client who tried to save money on a very basic model from another supplier. They soon found that the lack of precise control led to inconsistent results, costing them more in the long run. We helped them find a better-suited model that balanced cost and features for their specific needs.

Do Optional Accessories Significantly Add to the Rotary Evaporator Cost?

Got a base price but worried about hidden extras? Do you need all those fancy add-ons? Budgeting for accessories can indeed be tricky for many.

Yes, optional accessories like vacuum pumps, chillers, and specialized glassware can significantly increase the total cost. You should evaluate your specific application needs carefully to avoid unnecessary expenses.

When you're looking at the price of a rotary evaporator, it's very important to think about the whole system. The main unit is just one part. Many customers I speak with are surprised by how much accessories can add to the total investment. A vacuum pump is almost always essential, and its type – whether a diaphragm pump for oil-free operation or a more traditional oil-sealed pump – will affect cost and performance. We always ask about the solvents being used to recommend the right pump.

Chillers and Glassware Sets

A recirculating chiller is another common accessory, especially if you need to condense low-boiling point solvents efficiently or if your tap water is too warm or unreliable. Chillers improve solvent recovery rates a lot, which can save money on solvents over time, but they represent an upfront cost. Specialized glassware, like different sized evaporating or receiving flasks, bump traps for preventing sample foaming into the condenser, or spider-type flasks for multiple samples, will also add to the initial outlay. For example, our popular 5L rotary evaporator can be kitted out in many ways depending on the task.

Automation and Data Features

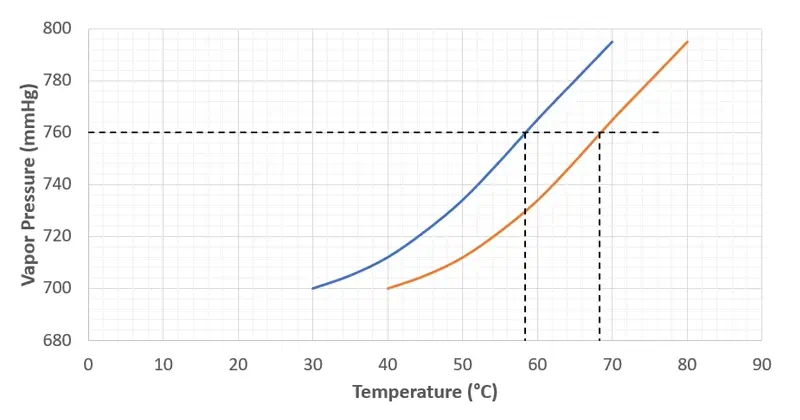

Some labs might also look for automated modules, such as those that control vacuum levels automatically based on vapor pressure, or systems that monitor solvent levels. Data logging capabilities for quality control or research records can also be an add-on. My advice is always to list your essential needs first. What processes will you run most often? What level of precision do you require? Then, we can discuss which accessories offer genuine benefits for your work versus those that are just 'nice-to-haves'. This way, we ensure you get a system that works effectively without overspending on features you might not use. It's about building a cost-effective solution tailored to your lab.

How Does Brand Reputation and Country of Origin Affect Pricing?

See big price differences between brands? Wonder if a "Made in China" label means lower quality or just better value? It is a common dilemma for buyers.

Established Western brands often command higher prices due to historical reputation and R&D investment. However, manufacturers like us in China offer competitive quality and innovation at a better price point due to lower production costs.

It's true that you'll see a range of prices for rotary evaporators based on the brand and where it's made. For many years, well-known brands from Europe or the USA have been seen as the top choice, and they often have higher prices. This is partly due to their long history, their investment in research, and their established service networks. People trust these names. However, the global market has changed a lot. As a Chinese manufacturer with over 16 years specializing in laboratory instrument exports, I can tell you that quality and innovation are not limited by geography.

The "Made in China" Advantage

We, at Zhengzhou Keda (ZZKD), focus on what we call "Made in China + International Quality." This means we leverage our technical expertise and efficient manufacturing processes to produce high-value equipment that meets stringent international standards, like ISO9001 and CE. We invest continuously in R&D to provide customized, high-cost-performance solutions. The advantage for you, the customer, is that you can get advanced technology and reliable equipment without paying the premium prices often associated with older, established Western brands. For instance, a client in South America recently switched to our equipment after using a European brand for years. They were amazed by the comparable performance and the significant cost savings, which allowed them to equip more of their lab within their budget.

Support and Trust

The key is to look beyond just the brand name or country of origin. You should look at the specifications, the quality of materials, the certifications, and very importantly, the after-sales support offered. We were one of the first in China to set up a 24/7 after-sales support team because we know how crucial reliable operation is for our global customers. We build long-term trust by being transparent and welcoming technical exchanges and factory visits. So, while brand and origin do play a role in price, focusing on proven quality, support, and overall value is a smarter approach for any lab.

What Are the Long-Term Operational Costs to Consider Beyond the Initial Purchase?

Focused on the upfront cost but worried about future expenses? Will your rotovap become a money pit? Smart buyers always think about the long-term implications.

Beyond the purchase, consider costs for electricity, consumables like seals and glassware, maintenance, and potential repairs. Choosing durable equipment and having good support can minimize these ongoing expenses.

The initial purchase price of a rotary evaporator is just the beginning of the story. I always encourage our customers to think about the total cost of ownership over the equipment's lifespan. Several factors contribute to these ongoing operational costs. Electricity is one; the heating bath, the motor, the vacuum pump, and a chiller if you use one, all consume power. While modern units are designed to be more energy-efficient, it's still a consistent expense.

Consumables and Maintenance

Consumables are another key area. Seals, typically made of PTFE or similar resistant materials, will wear out over time, especially with heavy use or aggressive solvents. They need regular inspection and replacement to maintain a good vacuum. Glassware, while durable, can break due to accidents or thermal shock if not handled correctly. Having spare flasks or condensers on hand might be wise, and this adds to costs. If you have an oil-based vacuum pump, the oil will need changing periodically. Regular maintenance, mostly cleaning and checking connections, is vital to prevent bigger problems. We provide detailed manuals, and our support team is always ready to guide users. For example, our rotary evaporator manual for models like the RE-2002 details routine checks.

Repairs and Downtime

Repair costs can also arise, though choosing robustly built equipment minimizes this. The availability and cost of spare parts are important. We ensure that spare parts for our equipment are readily available and offer lifetime cost-price service after the warranty period. This is part of our commitment to keeping customer maintenance costs low. Perhaps the biggest hidden cost is downtime. If a cheap, unreliable unit breaks down frequently, the lost research time or production output can be far more expensive than any initial savings. That's why investing in quality from a reputable manufacturer with good support ultimately saves money. I remember helping a university lab that was constantly repairing an old, low-quality unit. Switching to one of our more reliable models, even though the upfront cost was slightly higher, drastically reduced their downtime and improved their research output.

Conclusion

Understanding rotary evaporator costs means looking at size, features, brand, and long-term expenses. We aim to help you find the best value for reliable results.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

What Is a Rotary Evaporator? Beginner-Friendly Guide to Rotary Evaporation

Learn what a rotary evaporator is, how it works, and how it solves common solvent removal problems in laboratories and production. Clear, beginner-friendly ex...

Read MoreHow Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read More