What is Lab Scale Distillation Equipment and Why is it Essential for Your Research?

Struggling to purify compounds or separate solvents in your lab? Impure samples can ruin experiments and waste valuable resources. Find out how the right equipment changes this.

Lab scale distillation equipment is crucial for separating and purifying liquids based on their boiling points. It allows researchers to obtain high-purity substances, essential for accurate results and product development in various scientific fields.

As a company with over 16 years of experience in manufacturing and exporting laboratory instruments, we've seen firsthand how vital precise distillation is. Whether you are working in a university research lab, a pharmaceutical development facility, or a chemical processing plant, the right tools are absolute game-changers for your work. We have helped countless researchers and scientists achieve breakthroughs and streamline their processes with reliable and efficient distillation equipment. Trust me, investing in quality apparatus can make all the difference.

How Does Lab Scale Distillation Equipment Work to Purify Samples?

Confused by the different distillation methods? Unsure how heat and vacuum can lead to pure substances? We make the science simple and clear for you.

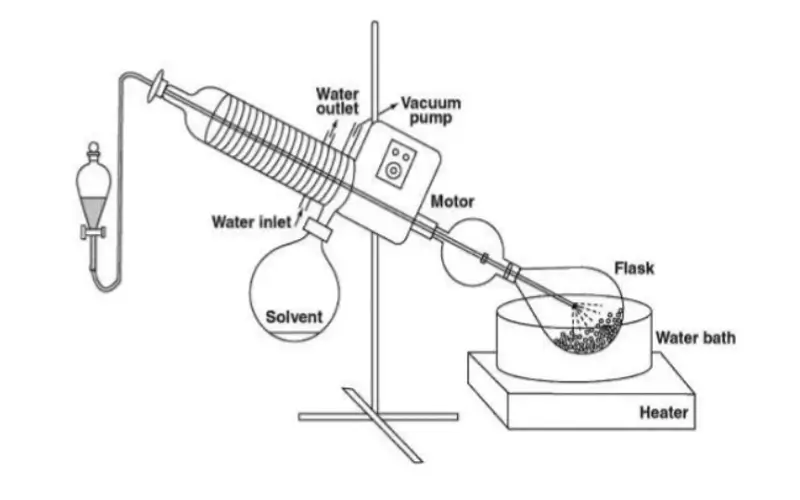

Lab distillation works by carefully heating a mixture to vaporize components with lower boiling points. These vapors are then cooled and condensed back into liquid form, now separated from less volatile substances.

Understanding the core of distillation can really help you choose and use your equipment effectively. It’s all about differences in how easily substances turn into vapor.

The Basic Principle: Boiling Point Differences

At its heart, distillation relies on the fact that different substances have different boiling points. When you heat a liquid mixture, the substance with the lower boiling point will start to vaporize more readily. This vapor is then collected and cooled, condensing it back into a purer liquid form. Simple distillation is great for separating liquids with significantly different boiling points. For liquids with closer boiling points, fractional distillation, which uses a fractionating column, provides better separation by offering multiple vaporization-condensation cycles. We've seen many labs start with simple setups and then realize they need more refinement for trickier separations. This is where specialized equipment truly shines, offering more control and efficiency than basic glassware assemblies. It's fascinating how this fundamental principle is applied in so many advanced ways in modern labs.

The Role of a Rotary Evaporator in Modern Labs

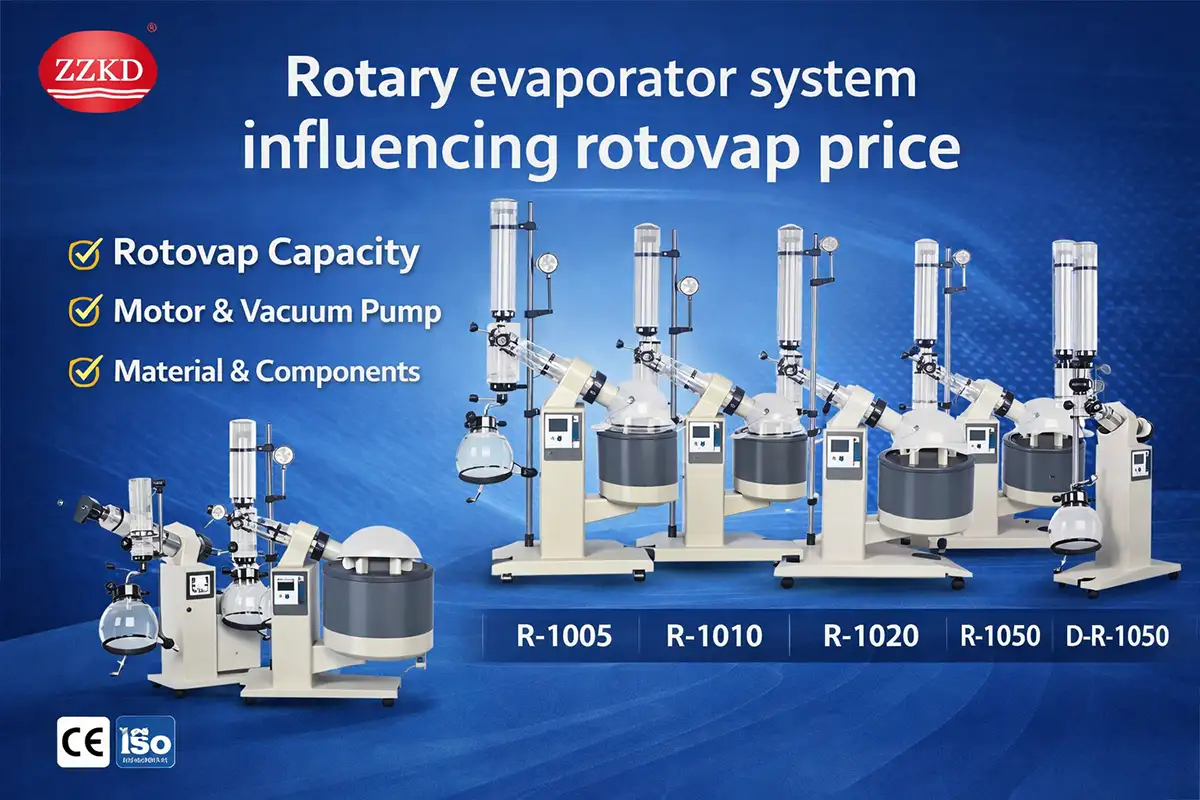

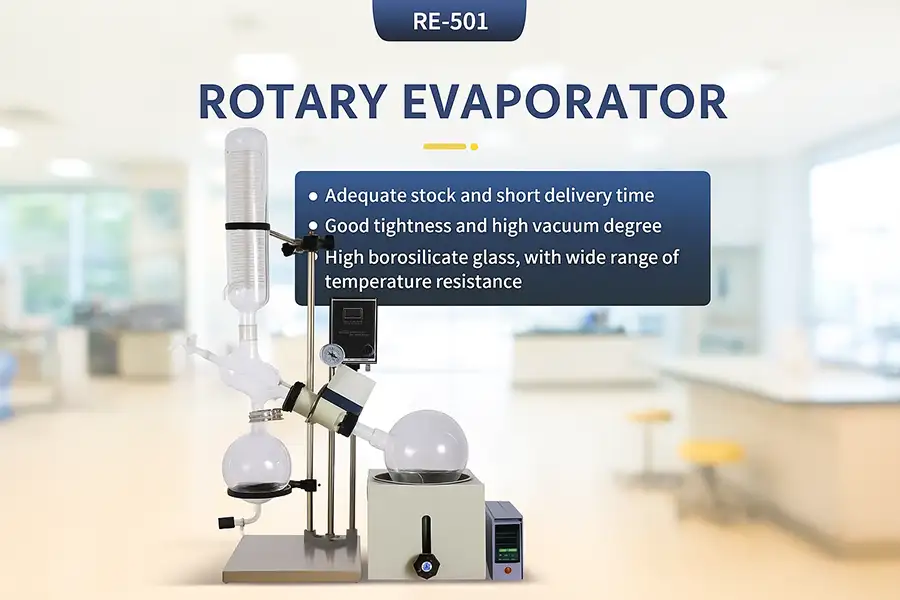

A laboratory rotary evaporator enhances the distillation process significantly. It uses a vacuum to lower the boiling points of solvents. This means you can distill at lower temperatures, which is crucial for heat-sensitive compounds. The flask containing the sample also rotates, which increases the surface area for evaporation and ensures even heating. This makes the process much faster and more efficient. As specialists in rotary evaporators, we've designed our units to be both user-friendly and highly effective. I remember a young researcher who was struggling with degrading their heat-sensitive plant extracts using traditional heating. Once they switched to one of our rotary evaporators, the difference was night and day for their project's success and yield purity. The gentle yet rapid solvent removal was exactly what they needed.

What Are the Key Types of Lab Scale Distillation Equipment Available Today?

Overwhelmed by the array of distillation equipment? Choosing the wrong type can be costly and inefficient. Let's explore the common options for your lab.

Common types include simple distillation setups, fractional distillation columns for closer boiling points, steam distillation for heat-sensitive organic compounds, and highly efficient rotary evaporators for solvent removal and concentration.

Navigating the options for distillation equipment can seem daunting, but it’s easier when you break it down by application and efficiency needs. We always try to guide our clients through this selection process.

Simple and Fractional Distillation Units

Simple distillation units are the most basic form, typically consisting of a flask, a condenser, and a receiving flask. They are best for separating liquids with very different boiling points (a difference of at least 25°C) or for separating liquids from non-volatile solids. Fractional distillation units are a step up. They include a fractionating column between the distillation flask and the condenser. This column provides a large surface area for repeated vaporization and condensation, leading to much better separation of liquids with closer boiling points. While effective, they can be slower and require careful control. We've noticed many academic labs use these for teaching basic principles, but for intensive research, more advanced solutions are often sought for speed and sample protection.

Steam Distillation

Steam distillation is a special technique used for separating organic compounds that are heat-sensitive and immiscible with water. Steam is passed through the mixture, causing the volatile compounds to co-distill with the steam at a lower temperature than their normal boiling points. This method is very common in the extraction of essential oils from plant materials. It’s a gentle process, but its applications are somewhat specific. We don't manufacture dedicated steam distillation units, but the principles of gentle evaporation are key in our rotary evaporator designs as well, especially when handling delicate natural products that could degrade under harsh conditions. It’s a classic technique that still holds immense value in certain industries.

The Versatile Rotary Evaporator

The rotary evaporator, or rotovap, is truly a workhorse in modern labs. Its main advantages are speed, efficiency, and the gentle treatment of samples. By reducing pressure with a vacuum pump, it lowers the solvent's boiling point, allowing for rapid evaporation without excessive heat. The rotation of the flask continuously spreads the sample into a thin film, maximizing the surface area for evaporation. This is perfect for solvent removal, concentration of solutions, and solvent recovery. We often recommend starting with a versatile small rotary evaporator for labs handling diverse samples, as it covers a wide range of needs effectively. Many of our clients appreciate how our rotary evaporators can also be used for reflux reactions or drying powders when configured appropriately.

| Feature | Simple Distillation | Fractional Distillation | Rotary Evaporator |

|---|---|---|---|

| Efficiency | Basic | Moderate | High |

| Speed | Slow | Moderate | Fast |

| Sample Sensitivity | Risk of overheating | Risk of overheating | Gentle (vacuum, rotation) |

| Solvent Recovery | Possible | Better | Excellent |

| Common Use | Basic purification | Close B.P. separation | Solvent removal, concentration |

Why is a Rotary Evaporator Often the Best Choice for Lab Scale Distillation?

Want faster, safer, and more efficient distillations? Traditional methods can be slow and damage your valuable samples. Discover a superior solution for your lab work.

Rotary evaporators excel due to their ability to distill under vacuum, lowering boiling points and protecting heat-sensitive materials. The rotating flask increases surface area for rapid, efficient evaporation.

When we talk to customers, many are looking for that perfect balance of speed, gentleness, and versatility. In many lab scale distillation scenarios, the rotary evaporator consistently delivers on these fronts.

Enhanced Efficiency and Speed

The design of a rotary evaporator is inherently geared towards efficiency. The combination of reduced pressure (vacuum) and the increased surface area from the rotating flask dramatically speeds up the evaporation process. Solvents are removed much more quickly than with static distillation methods. We've seen labs reduce their solvent removal times by more than half after implementing our rotary evaporators. This isn't just about saving time; it's about increasing throughput and allowing researchers to move on to the next stages of their work faster. For a busy lab, this boost in productivity is invaluable. Plus, the continuous feeding options on some models further enhance this for larger volumes.

Gentle on Your Samples

One of the most significant advantages of using a rotary evaporator is its gentle treatment of samples. Many chemical and biological compounds are heat-sensitive (thermally labile) and can degrade or decompose at high temperatures. Because rotary evaporators operate under vacuum, the boiling point of the solvent is significantly lowered. This means you can effectively distill or concentrate your sample at much lower bath temperatures, preserving the integrity of your valuable compounds. This is particularly crucial in pharmaceutical research, natural product chemistry, and biotechnology, where sample integrity is paramount. We always emphasize this aspect because we know how much effort goes into preparing these samples.

Versatility for Various Applications

Rotary evaporators are not just for simple solvent removal. They are incredibly versatile tools. They can be used for concentrating solutions, reclaiming solvents (which is both cost-effective and environmentally friendly), drying powders or residues, and even for certain types of reflux reactions when equipped with the right accessories. Our 5L rotary evaporator is a particularly popular choice among our clients because it hits a sweet spot in terms of capacity and performance, handling a wide range of tasks from research to pilot scale. As a manufacturer, we ensure our equipment meets stringent international quality standards like ISO9001 and CE, giving you confidence in its reliability across diverse applications.

What Factors Should You Consider When Choosing Lab Scale Distillation Equipment?

Afraid of investing in the wrong equipment? Choosing the right distillation setup involves many factors. We guide you to make an informed and confident decision.

Key factors include the volume and nature of your samples, required purity, solvent types, available vacuum source, temperature control needs, and safety features. Budget and lab space also matter.

Selecting the right lab scale distillation equipment is a critical decision that impacts your lab's efficiency and the quality of your results. We always advise our clients to think through several key aspects before making a purchase.

Sample Characteristics and Volume

The first thing to consider is your sample. What is its typical batch size? Are you working with a few milliliters or several liters? This will dictate the required capacity of the evaporating flask and heating bath. For smaller, exploratory work, a compact unit is fine, but for routine processing or pilot studies, you might need something larger. For example, our 10l rotary evaporator is excellent for medium-scale operations, while our large scale rotary evaporator models cater to even bigger volumes. Also, consider the heat sensitivity of your compounds and the volatility of the components you are trying to separate. This will influence the type of temperature and vacuum control you need.

Operational Parameters

Think about the specific conditions your processes require. What temperature range do you need for your heating bath? Does it need to be water or oil? What level of vacuum is necessary, and do you need precise vacuum control? The efficiency of a rotary evaporator, for instance, heavily depends on a good vacuum source and stable temperature. Also, consider the rotation speed control; different applications might benefit from different speeds. We design our equipment with a wide range of adjustable parameters to give you maximum flexibility. It's also worth checking the compatibility of the glassware and seals with the solvents you plan to use, to prevent any chemical reactions or degradation of the equipment over time.

Safety and Ease of Use

Safety in the lab is non-negotiable. Look for equipment with robust safety features such as high-quality borosilicate glassware, safety shields (especially for vacuum operations), over-temperature protection for the heating bath, and sparkless motors if you're working with flammable solvents. Ease of use is also important for productivity and to minimize operational errors. Intuitive controls, clear displays, and easy assembly/disassembly for cleaning are all beneficial. As manufacturers with over 16 years of international export experience, safety and reliability are paramount in all our designs. Our equipment is built to meet global standards, ensuring peace of mind for our users. We often hear from clients how much they appreciate the straightforward operation of our units.

Support and Service

Finally, consider the long-term support. What is the warranty period? Are spare parts readily available? What kind of after-sales service does the manufacturer or supplier offer? Equipment downtime can be costly. We pride ourselves on being the first manufacturer in China to establish a 24/7 after-sales support team. We believe that providing excellent service, including free maintenance during the warranty and lifetime cost-price service, is just as important as providing high-quality equipment. This commitment ensures our customers can operate their equipment efficiently and stably for years to come.

Conclusion

Choosing the right lab scale distillation equipment, especially a versatile rotary evaporator, significantly boosts lab efficiency and research success. We are here to help you select the best.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

What Is a Rotary Evaporator? Beginner-Friendly Guide to Rotary Evaporation

Learn what a rotary evaporator is, how it works, and how it solves common solvent removal problems in laboratories and production. Clear, beginner-friendly ex...

Read MoreHow Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read More