How Does a Rotary Evaporator Work? A Complete Guide

Rotary evaporators are essential tools in chemical laboratories for efficient solvent removal. This comprehensive guide explains the science behind rotary evaporation, its applications, and the benefits of various models.

vs traditional methods

Compound preservation

Science Simplified

Key Operating Principles

A rotary evaporator operates on three fundamental physical principles:

Reduced Pressure

Lowering system pressure decreases solvent boiling point, preventing thermal degradation.

Rotation

Spinning the flask increases surface area and creates a thin film for rapid evaporation.

Condensation

Cooled condenser captures vaporized solvent for recovery or disposal.

Why is reducing pressure important in a rotary evaporator?

Lowering pressure significantly reduces the solvent's boiling point. This allows evaporation at temperatures far below normal boiling points, preserving heat-sensitive compounds that would degrade at higher temperatures. For example, water evaporates at just 30°C under vacuum as opposed to 100°C at sea level pressure.

Core Technology

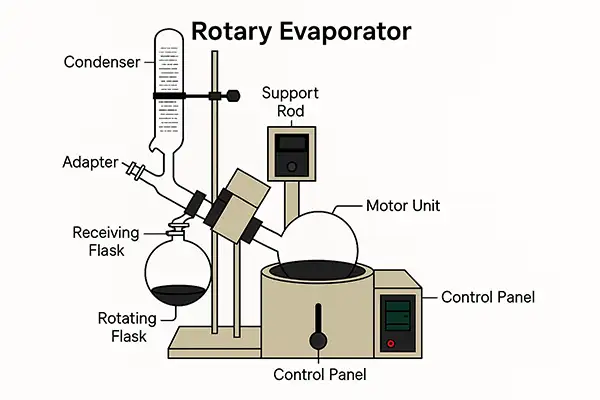

Main Components Explained

Rotating Flask

Holds sample & creates thin film

Heating Bath

Gentle thermal energy source

Condenser

Cools vapor back to liquid

Receiving Flask

Collects condensed solvent

Vacuum Pump

Reduces system pressure

Control System

Precise operation management

Procedure

Step-by-Step Evaporation Process

Sample Placement

The solution containing the solvent is placed in the evaporation flask, filling no more than half of its capacity to prevent overflow during rotation.

Immersion & Rotation

The flask is partially submerged in the temperature-controlled water or oil bath and set to rotate slowly at 50-200 rpm, creating a uniform solvent film.

Vacuum Application

The vacuum pump reduces system pressure to 10-100 mbar (depending on solvent) to lower the boiling point of the solvent.

Gentle Heating

The bath heats the rotating solvent to a temperature below its atmospheric boiling point, causing evaporation.

Vapor Condensation

Solvent vapor travels upward through the vapor tube to the condenser where it's cooled and liquified.

Solvent Collection

The condensed liquid drips down the condenser coils into the collection flask where it's recovered or disposed of.

What is the main advantage over simple distillation?

Rotary evaporation is significantly more efficient and preserves sensitive compounds through lower operating temperatures. This process achieves higher evaporation rates due to the large solvent surface area created by rotation. Additionally, the integrated vacuum system allows for continuous solvent removal without interruption, making it perfect for heat-sensitive compounds in analytical chemistry, pharmaceutical purification, and food science applications.

Can rotary evaporators be used for large-scale production?

Absolutely. While standard rotary evaporators are designed for laboratory use, industrial-scale systems can process substantial volumes. For example, the RE-5002 Large Scale System features a 10-liter evaporation capacity, automated controls, and advanced safety systems, making it suitable for pilot plants and production facilities.

Industry Applications

Pharmaceuticals

Purification of drug compounds and removal of reaction solvents while preserving molecular integrity.

Recommended Models

Top-rated rotary evaporators by capacity and features:

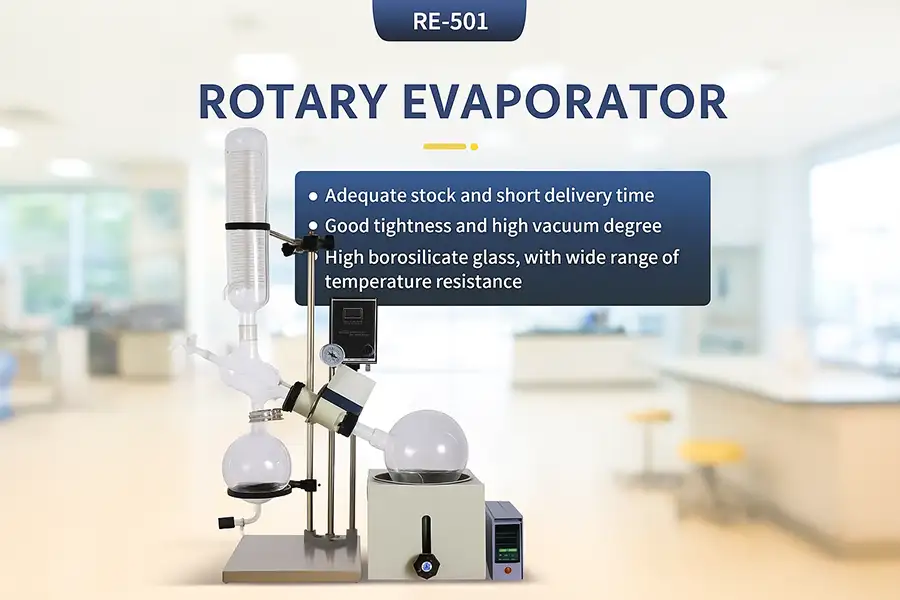

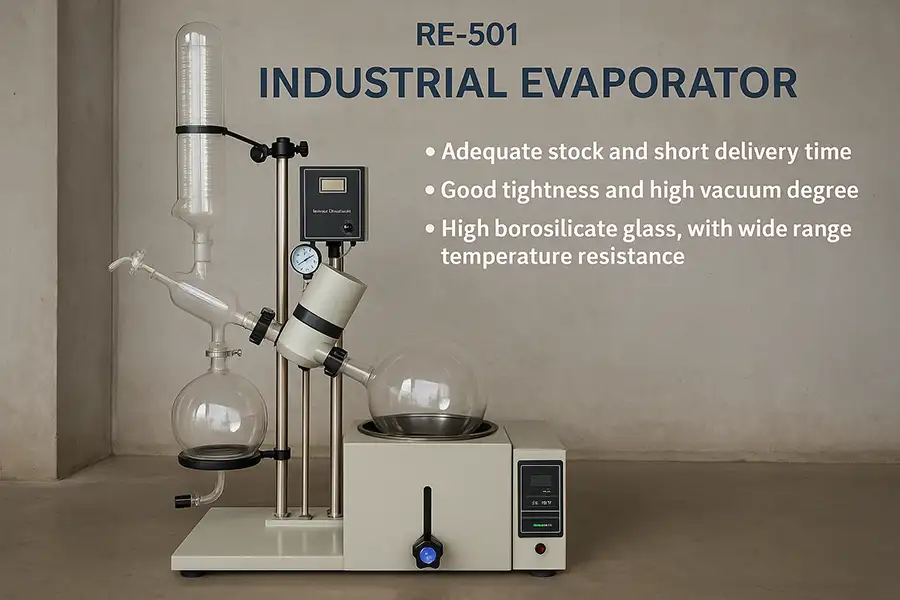

RE-201D 2L System

Ideal for small laboratoriesRE-501 5L Professional

Enhanced capacity and efficiencyR-1020 20L Industrial

Industrial-scale productionE-2000ABE Mini

Compact benchtop solution

Technical Information

Maintenance & Safety Guidance

Routine Maintenance

Daily: Clean evaporating and collecting flasks using appropriate solvents

Weekly: Perform safety checks on vacuum seals and rotating joints

Monthly: Replace vacuum pump oil and check refrigeration levels

Quarterly: Inspect electrical components and temperature sensors

Annual: Professional calibration and comprehensive system inspection

Critical Safety Practices

Never overfill the evaporation flask (max 50% capacity)

Implement secondary protection against implosion with safety glasses

Only use bath fluids appropriate for the temperature range

Always release vacuum pressure before disconnecting components

Place emergency release valves and fire suppression equipment nearby

Scientific Outlook

The Future of Evaporation Technology

Laboratory evaporation technology continues to evolve rapidly. According to recent studies at MIT and ETH Zurich, emerging trends include:

Automated Systems

Self-regulating, AI-driven evaporation that automatically adjusts parameters to maximize efficiency and prevent bumping.

Energy Recovery

New designs capture thermal energy from condensation to preheat incoming materials, reducing energy consumption by 30%.

Parallel Processing

Multi-rotovap systems with synchronized controls allow simultaneous evaporation of multiple solvent systems within a fume hood.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

What Is a Rotary Evaporator? Beginner-Friendly Guide to Rotary Evaporation

Learn what a rotary evaporator is, how it works, and how it solves common solvent removal problems in laboratories and production. Clear, beginner-friendly ex...

Read MoreHow Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read More