Rotary Evaporator for Sale: A Complete Guide

Understanding rotary evaporator machines, their applications, and how to choose the ideal solution for your lab or industrial needs.

Explore ModelsWhat is a Rotary Evaporator?

The essential tool for solvent removal in modern laboratories.

A rotary evaporator, often called a "rotovap", is a specialized laboratory device designed for the efficient, gentle removal of solvents from samples via evaporation. It combines reduced pressure, controlled heating, and rotating motion for optimal solvent extraction while preserving sensitive compounds.

Rotary evaporators have become indispensable in chemistry, biochemistry, and pharmaceutical industries due to their ability to process solvents without damaging heat-sensitive materials.

Efficient Evaporation

Removed solvents 50% faster than conventional methods

Temperature Control

Preserves heat-sensitive compounds and materials

Enhanced Safety

Built-in safety features minimize operational risks

Versatile Applications

Works across multiple industries and solvent types

How Does a Rotary Evaporator Work?

Rotary evaporators operate on a sophisticated principle: samples in a rotating flask are partially submerged in a heated bath. The rotation creates an optimal evaporation surface area, while simultaneous vacuum pressure reduces the solvent's boiling point, enabling low-temperature vaporization.

Sample Loading & Rotation

The sample is placed in a rotating flask that increases surface area for evaporation

Vacuum Application

Reduced pressure significantly lowers the boiling point of solvents

Controlled Heating

The flask rotates in a water bath at precise temperature settings

Vapor Condensation

Solvent vapors travel to a cooled condenser for liquefaction

Solvent Collection

Liquefied solvent collects in a receiving flask for disposal or reuse

Applications of Rotary Evaporators

Pharmaceutical Research

Drug discovery and purification processes

Natural Product Extraction

Essential oils and plant-derived compounds

Food & Beverage Industry

Concentration of flavors and aromas

Environmental Analysis

Water sample concentration for testing

Industry Impact

According to MIT LabTech Research, automation integration in rotary evaporators has increased processing efficiency by 38% and reduced solvent costs by 27% in pharmaceutical manufacturing.

Advanced rotovap systems with automation are projected to increase lab productivity by over 25% by 2035, making them crucial investments for any research facility.

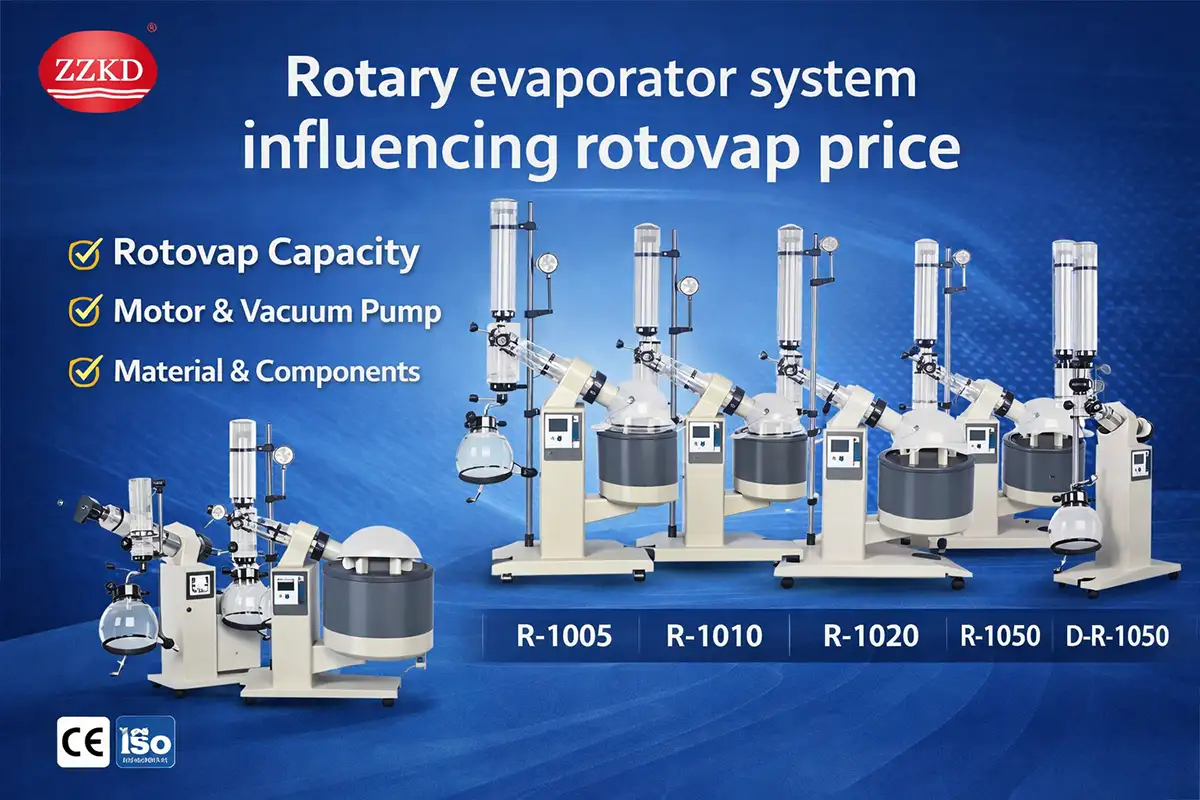

Choosing the Right Rotary Evaporator

Selecting the right rotary evaporator depends on your sample volume, solvent characteristics, and workflow requirements. Each model offers distinct advantages based on your laboratory's needs.

| Model | Capacity | Rotation Speed | Temperature Range | Application | Details |

|---|---|---|---|---|---|

| RE-201D | 2L | 10-180 RPM | 0-99°C | Small-scale lab work | Learn More |

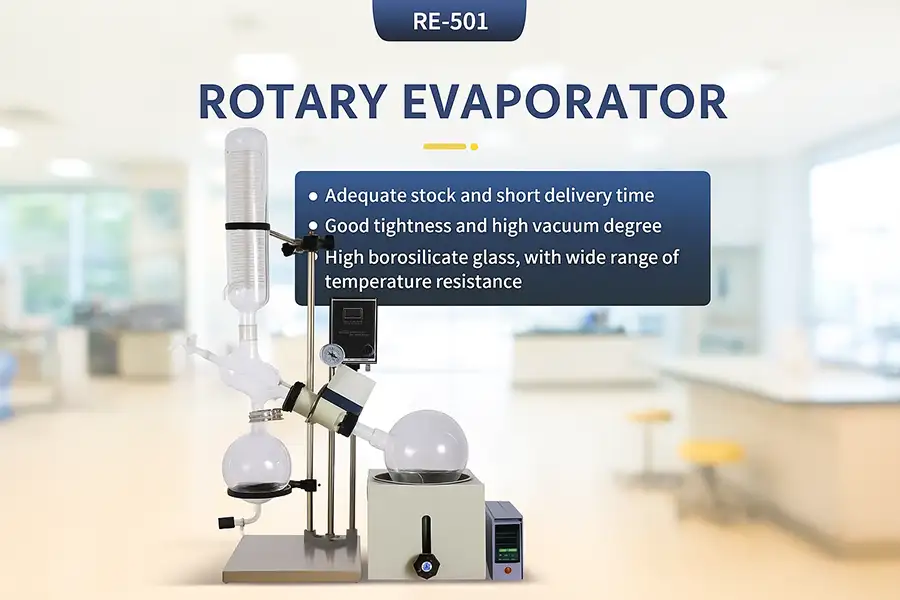

| RE-501 | 5L | 10-180 RPM | -20~99°C | Medium-scale research | View Details |

| RE-1002 | 10L | 10-120 RPM | -20~99°C | Industrial pilot scale | Industrial Use |

| RE-5002 | 50L | 5-80 RPM | RT~90°C | Large-scale production | Production Model |

Safety & Maintenance

Proper maintenance extends equipment lifespan and ensures optimal performance:

Daily Inspection Checklist

Examine vacuum seals to prevent leaks

Check bath fluid level and quality

Ensure ventilation holes remain unobstructed

Monthly Maintenance Routine

Clean glass components with appropriate solvents

Lubricate moving components as recommended

Calibrate temperature and rotation controls

Vacuum Pump Care

Regularly change oil (for oil-based pumps)

Check for unusual noises or vibrations

Monitor pump performance metrics

Where to Find Rotary Evaporators

When evaluating rotary evaporators for sale, prioritize established suppliers with comprehensive product offerings:

Manual Rotary Evaporators

Best SellerPerfect for laboratories requiring precision control

Large Scale Production Systems

PopularFor industrial applications requiring continuous operation

Advanced Laboratory Models

New ArrivalDigitally controlled systems with automation features

Professional Advice

Selecting the right rotary evaporator requires consideration of:

Volume requirements per batch

Solvent characteristics and evaporation points

Automation and safety protocols needed

Space constraints and compatibility

Conclusion

Rotary evaporators have become foundational equipment in modern chemical processing across industries.

With their advanced solvent removal capabilities, precise temperature controls, and adaptability to diverse applications, rotary evaporators provide critical efficiency in both research settings and industrial-scale operations.

Investing in appropriate rotary evaporation technology, whether for initial discovery research (2-5L) or production-scale manufacturing (10-50L), delivers tangible benefits:

Superior compound preservation

Maintains stability of sensitive molecules through low-temperature evaporation

Significant cost savings

Reduces solvent consumption by up to 30% compared to conventional methods

Enhanced productivity

Automated systems allow unattended operation for overnight processing

Have Questions?

Our lab equipment specialists are available to help you:

Identify optimal system configuration

Provide technical documentation

Arrange equipment demonstrations

Discuss application requirements

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

What Is a Rotary Evaporator? Beginner-Friendly Guide to Rotary Evaporation

Learn what a rotary evaporator is, how it works, and how it solves common solvent removal problems in laboratories and production. Clear, beginner-friendly ex...

Read MoreHow Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read More