Rotary evaporators, or rotovaps are indispensable equipment in labs worldwide, enabling efficient solvent removal through evaporation while preserving temperature-sensitive compounds.

Essential Rotary Evaporator Components

Understanding each rotary evaporator part is fundamental to optimizing laboratory processes. These sophisticated systems combine thermal and mechanical principles for precise solvent separation.

Rotating Flask: Increases evaporation surface area through controlled rotation

Heating Bath: Provides carefully regulated temperatures for solvent evaporation

Condenser: Rapidly cools vapors returning them to liquid form

Vacuum System: Lowers boiling points to protect heat-sensitive compounds

| Part | Function | Key Characteristics |

|---|---|---|

| Rotating Flask | Holds the liquid mixture; rotates to increase evaporation surface area | Borosilicate glass, adjustable rotation speed |

| Heating Bath | Maintains controlled temperatures for efficient solvent evaporation | Digital thermostat, temperature safety cut-off |

| Condenser | Cools vapor and transforms it back into liquid form | Coil or coiled coil design, efficient heat transfer |

| Receiving Flask | Collects the condensed solvent after separation | Large capacity, easy-to-remove design |

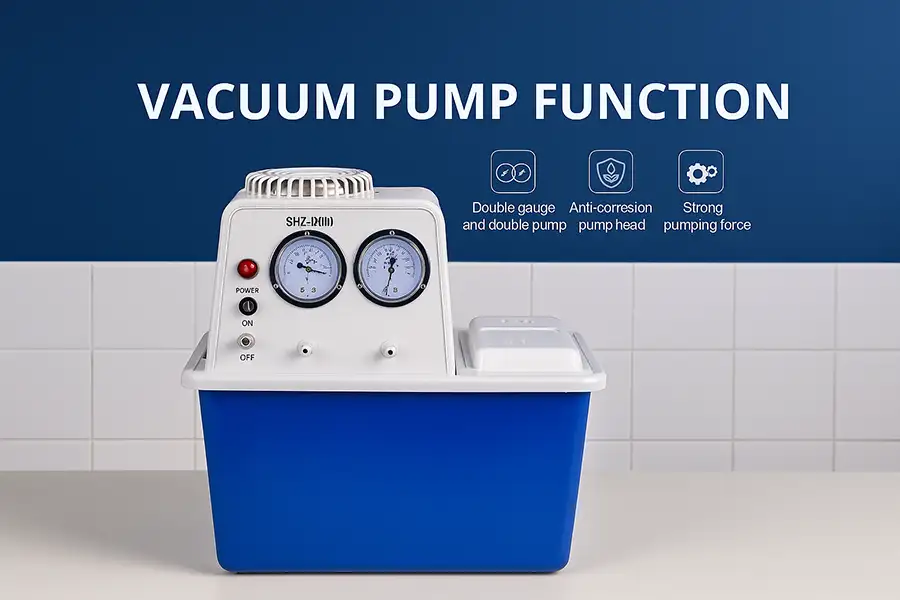

| Vacuum Pump | Reduces system pressure to lower boiling points | Variable vacuum strength, chemical-resistant |

| Control Panel | Adjusts rotation speed, bath temperature, and settings | Touchscreen interface, programmable protocols |

Answer: The vacuum pump creates sub-atmospheric pressure conditions that dramatically reduce solvents' boiling points. This innovation allows for low-temperature evaporation that:

Prevents degradation of heat-sensitive compounds

Accelerates evaporation by up to 200%

Reduces energy consumption by 30-40%

Enables processing of solvents with diverse boiling points

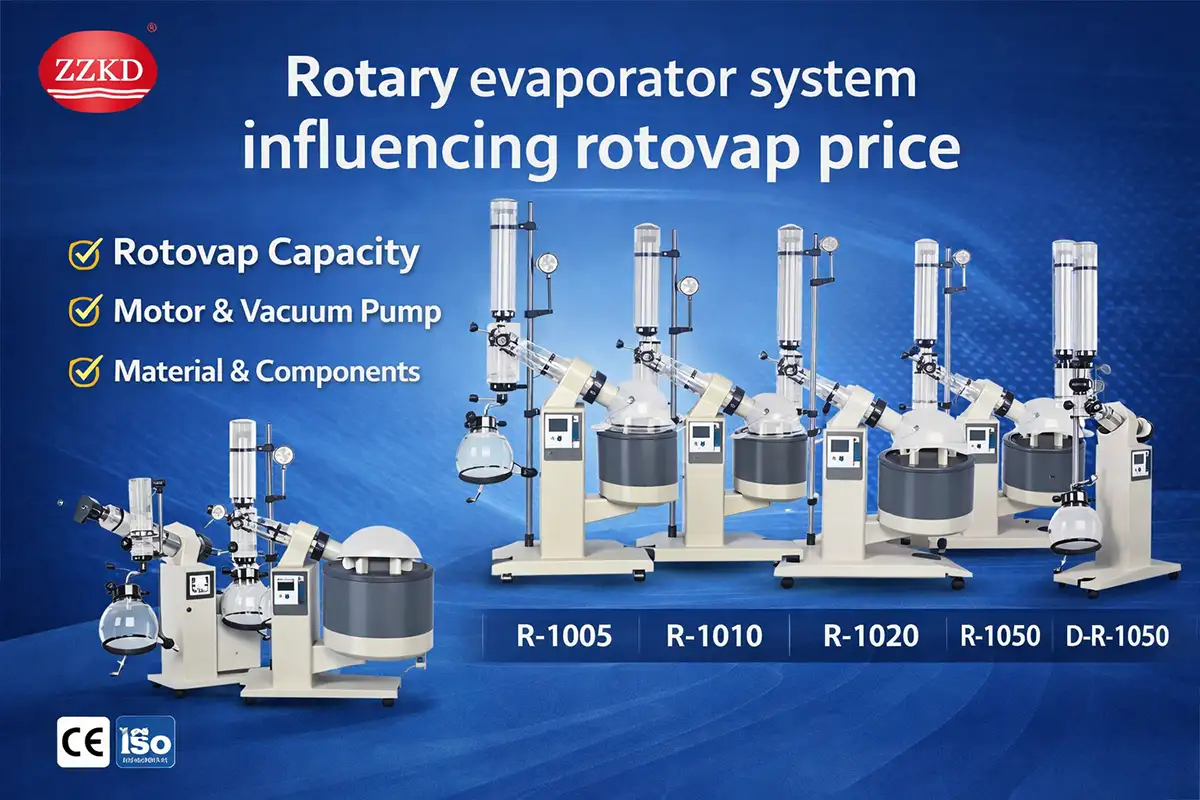

Optimizing Rotary Evaporator Selection

Choosing the ideal rotary evaporator system requires matching specifications to operational requirements:

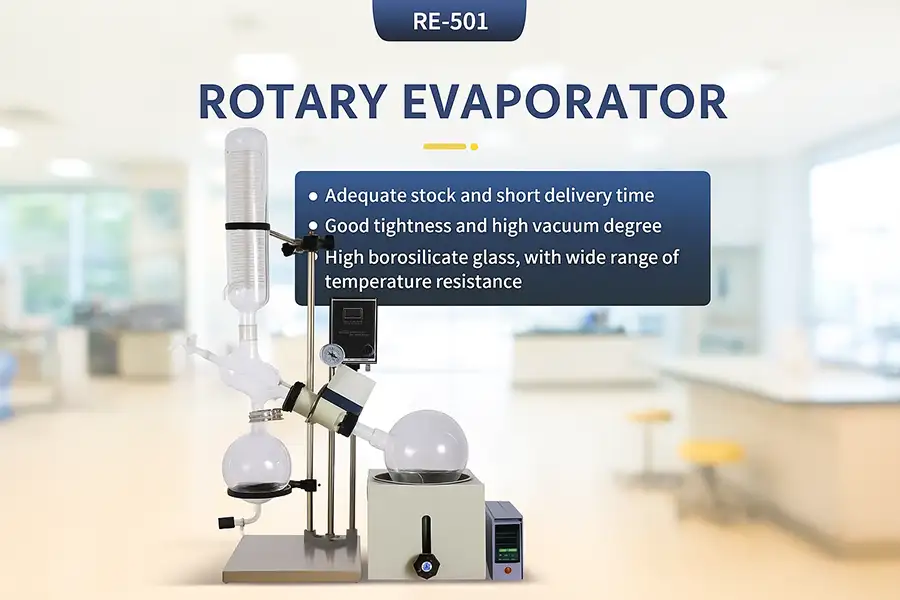

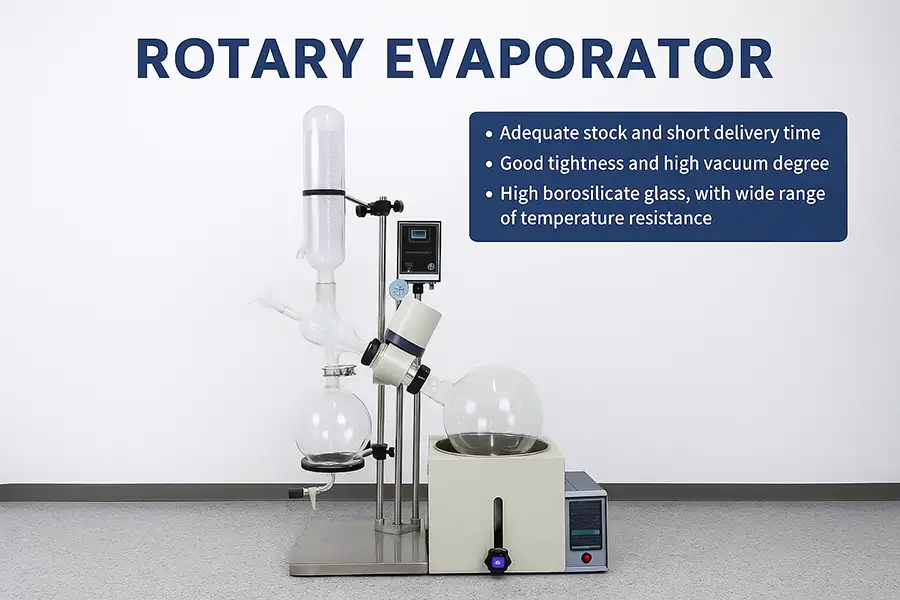

RE-501 5L Rotary Evaporator

Perfect balance between research capability and production capacity for academic and industrial labs.

View Specifications

RE-2002 Manual Rotary Evaporator

Precision control through manual adjustments for intricate experiments requiring detailed oversight.

View Specifications

R-1020 20L Laboratory Unit

Industrial-scale processing capacity for high-volume solvent removal in pharmaceutical manufacturing.

View SpecificationsAnswer: Manual systems excel in teaching environments and research applications requiring minute-to-minute adjustments. Automated units provide superior results when:

Processing multiple batches consecutively

Reproducibility is mission-critical

Limited technical staff is available

Integration with laboratory information systems is required

Essential Maintenance Procedures

Regular maintenance preserves accuracy and extends operational lifespan:

Glassware Cleaning: Weekly acetone rinse prevents residue accumulation

Seal Inspection: Monthly examination for vacuum integrity

Bath Maintenance: Quarterly thermal fluid replacement

Calibration: Bi-annual performance verification

Mechanical Lubrication: Annual servicing of moving components

Answer: Meticulous maintenance impacts both performance and operational safety:

15-20% increase in evaporation efficiency

5x reduction in vacuum seal failures

Consistent temperature accuracy (±0.5°C)

Prevents solvent cross-contamination

Extends equipment lifespan by 40-60%