What Are the Disadvantages of Rotary Evaporator?

Struggling with slow evaporation or worried about sample bumping in your rotary evaporator? These common issues can waste time and valuable materials in the lab.

Rotary evaporators can have disadvantages like potential sample bumping, limitations with high-boiling point solvents, reliance on vacuum quality, and the cost of associated peripherals like pumps and chillers. They also require careful operation to avoid breakage.

We've been manufacturing and exporting lab equipment like rotary evaporators for over 16 years at ZZKD. We understand they're workhorses in many labs. But like any tool, they aren't perfect. Knowing the potential downsides helps you use them better or decide if it's the right tool for your specific job. Let's explore some key areas related to rotary evaporators that often come up in discussions with our customers worldwide.

How does rotary evaporator price affect your purchasing decision?

Worried about the investment cost for a rotary evaporator? Balancing budget constraints with the performance and features needed for your specific applications can be challenging.

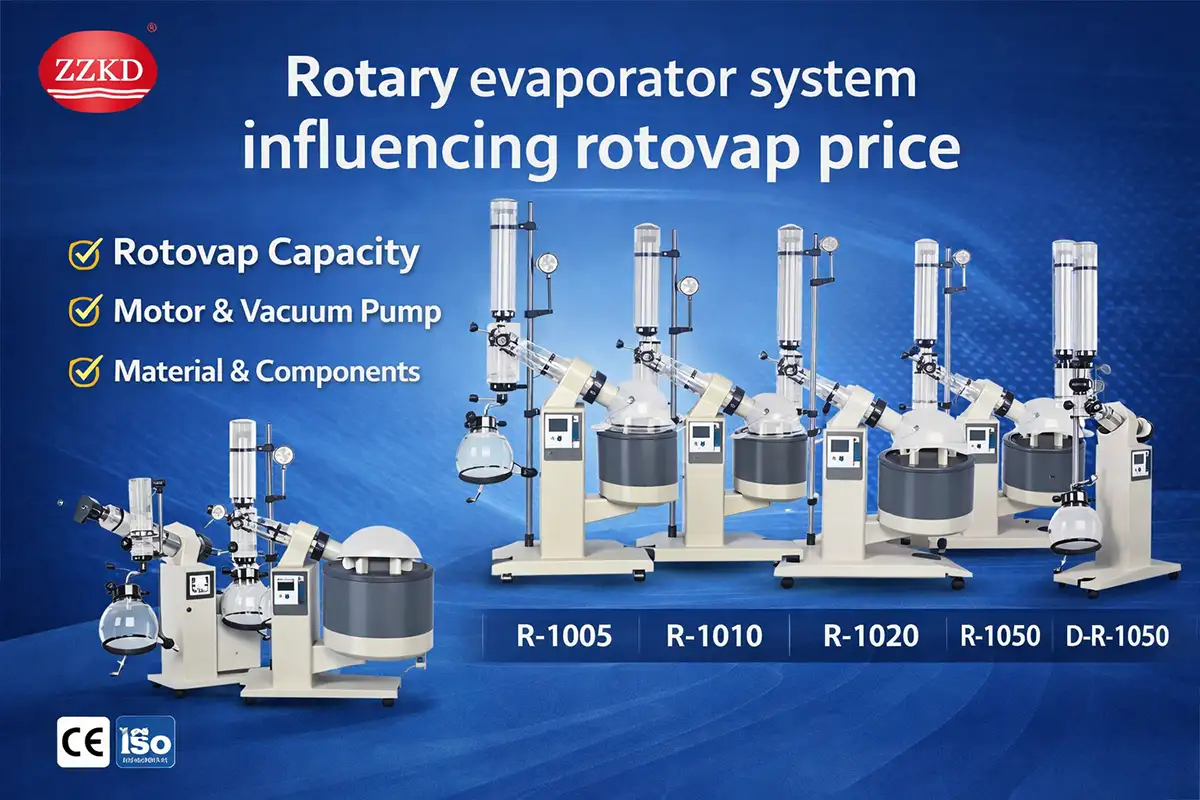

Rotary evaporator prices vary widely based on capacity, features (like digital controls, lift type), brand reputation, and included accessories (vacuum pump, chiller). Budget models exist, but high-performance or large-scale systems represent a significant investment for many labs.

When you're looking at buying a rotary evaporator, the price tag is often the first thing you notice. But what really goes into that cost? As a manufacturer, we see the price influenced by several key factors. Understanding these helps you figure out if you're getting good value.

Key Factors Influencing Price

Size/Capacity: Larger evaporating flasks (e.g., 10L, 20L, 50L) naturally cost more than standard 1L or 2L lab models due to more materials and robust construction needed.

Features & Automation: Manual lift vs. motorized lift, basic analog controls vs. programmable digital interfaces with timers and vacuum control – these add complexity and cost.

Glassware Quality: High-quality borosilicate glass (like GG-17 or Borosilicate 3.3) is standard, but specialized coatings or designs can increase the price.

Sealing System: Durability and chemical resistance (e.g., PTFE seals) are crucial for longevity and affect cost.

Brand Reputation & Support: Established brands might command higher prices due to perceived reliability and support networks. We at ZZKD focus on balancing cost with international quality standards (ISO, CE) and strong after-sales support.

Bundling: Sometimes, units are sold as packages including a vacuum pump and chiller. This can seem convenient, but it's worth checking if the bundled components are ideal for your needs.

Beyond the Initial Cost

Remember to consider the Total Cost of Ownership (TCO). You'll likely need a compatible vacuum pump and a chiller or cooling water source. These are often separate purchases and add significantly to the overall setup cost. Also factor in potential maintenance and spare parts like seals over the equipment's lifespan.

Our goal at ZZKD has always been to offer equipment that hits the sweet spot – reliable, certified, and feature-rich enough for demanding international markets, but without the premium price tag often associated with some older brands. We achieve this through efficient manufacturing and direct exporting.

Why is choosing the right vacuum pump for rotary evaporator so critical?

Is your rotary evaporator underperforming due to the wrong vacuum? An unsuitable pump leads to frustratingly slow evaporation, poor solvent recovery, and potential instrument contamination or damage.

The vacuum pump is absolutely crucial for rotary evaporation; its primary job is to lower the system pressure, which in turn lowers the solvent's boiling point. Choosing the wrong pump type or capacity leads directly to inefficient operation, solvent loss, or even pump damage from incompatible chemicals.

Think of the vacuum pump as the engine driving your rotary evaporator's efficiency. Without the right vacuum level, you simply won't achieve effective evaporation, especially for solvents that aren't extremely volatile. We often get questions from customers about optimizing their setup, and the vacuum pump is usually a key part of that conversation.

Understanding the Pump's Role

The core principle of rotary evaporation is removing solvent at a lower temperature than its normal boiling point to protect sensitive samples. This is only possible by reducing the pressure inside the system using a vacuum pump. The lower the pressure, the lower the temperature needed in the heating bath.

Key Selection Criteria

Ultimate Vacuum Level: The pump must be able to reach a pressure significantly lower than the target vapor pressure of your solvent at your desired condensing temperature (usually determined by your chiller or tap water). Check solvent vapor pressure charts!

Pumping Speed (Flow Rate): Measured in L/min or m³/h, this determines how quickly the pump can evacuate the system and handle the solvent vapors being generated. A higher flow rate generally means faster evaporation, especially for larger systems or higher vapor loads.

Chemical Resistance: This is non-negotiable. Most rotary evaporation involves organic solvents. You need a pump designed to handle these without corroding or failing. Chemically resistant diaphragm pumps (often with PTFE heads and diaphragms) are the standard choice for most applications. Oil-sealed rotary vane pumps offer deeper vacuum but are less chemically resistant and risk oil contamination unless protected by cold traps.

Vacuum Control: For precise work, especially with mixed solvents or sensitive samples, a vacuum controller is highly recommended. This allows you to set and maintain a specific vacuum level, preventing bumping and optimizing separation. Some pumps have integrated controllers.

Common Mistakes

Using a pump that doesn't pull a deep enough vacuum results in slow or no evaporation. Using a pump without adequate chemical resistance leads to rapid failure and costly replacements. Not matching the pumping speed to the system size can also be inefficient. As suppliers, we always advise customers to consider the solvents they'll use most often when selecting a pump – it's as important as the evaporator itself.

What makes a lab rotary evaporator a standard piece of equipment?

Setting up a new lab or upgrading essential equipment? Understanding the fundamental role and common variations of lab rotary evaporators is key to planning efficient research workflows.

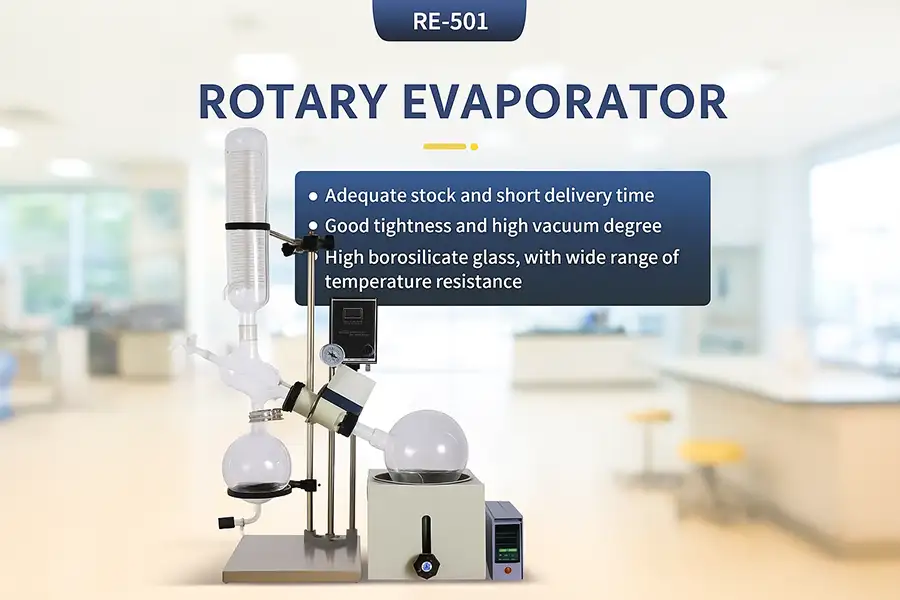

A lab rotary evaporator is standard equipment primarily because it offers an efficient and gentle method for removing solvents from samples by evaporation under reduced pressure. Its versatility makes it indispensable in chemistry, biology, pharmaceutical, and even food science labs worldwide.

Walk into almost any chemistry or related research lab, and you're likely to see a rotary evaporator, often called a "rotovap." We've exported thousands of these units over the years to labs in 87 countries, and their popularity stems from a few core strengths that make them so useful for everyday lab tasks.

How it Works Simply

The genius of the rotovap lies in combining several principles:

Rotation: Spinning the evaporation flask creates a thin film of the sample liquid on the inner surface. This increases the surface area dramatically, speeding up evaporation.

Heating: A water or oil bath gently heats the flask, providing the energy needed for the solvent to vaporize.

Reduced Pressure: A vacuum pump lowers the pressure inside the system, reducing the solvent's boiling point, allowing evaporation at lower temperatures and protecting heat-sensitive compounds.

Condensation: A condenser, cooled by circulating water or a chiller, turns the solvent vapor back into liquid, which is collected in a receiving flask. This allows for solvent recovery.

Common Applications

Its ability to handle these tasks efficiently makes it a lab staple:

| Application | Description |

| Solvent Removal | Most common use: removing solvent after synthesis or extraction to isolate the product. |

| Concentration | Reducing the volume of a solution. |

| Recrystallization | Concentrating a solution to induce crystallization. |

| Solvent Recycling | Recovering and potentially reusing expensive or hazardous solvents. |

| Sample Drying | Removing residual solvents from solids or oils. |

Variations and Accessories

While the basic principle is the same, you'll find variations like different flask sizes (from mL scale up to 50L or more in our product line), manual or automated lifting mechanisms for the flask, and digital controls. Essential accessories that complete the system include the vacuum pump, a cooling source (chiller or tap water), vacuum tubing, and sometimes optional items like vacuum controllers or vapor traps for very volatile solvents.

Its combination of speed, gentleness, and efficiency for solvent removal is why the lab rotary evaporator has become such a fundamental tool across so many scientific disciplines we serve.

Conclusion

Understanding rotary evaporator disadvantages, price factors, vacuum pump needs, and general lab use helps you choose and operate this essential equipment effectively for your specific applications and research goals.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

What Is a Rotary Evaporator? Beginner-Friendly Guide to Rotary Evaporation

Learn what a rotary evaporator is, how it works, and how it solves common solvent removal problems in laboratories and production. Clear, beginner-friendly ex...

Read MoreHow Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read More