What is Rotary Evaporator Distillation and How Can It Benefit Your Lab?

Struggling with slow solvent removal or sample degradation? Traditional methods can be inefficient. Rotary evaporators offer a gentler, faster, and more controlled solution for your laboratory processes.

Rotary evaporator distillation is a technique that gently and efficiently removes solvents from samples. It works by evaporation under reduced pressure while rotating the sample flask. This benefits your lab by improving speed, efficiency, and protecting heat-sensitive materials.

As a company that has specialized in manufacturing and exporting laboratory equipment like rotary evaporators for over 16 years, we've seen firsthand how crucial this technology is. Many of our customers come to us looking for ways to improve their distillation processes. They want something faster, more reliable, and gentler on their valuable samples. Rotary evaporation, often called "rotovap," provides exactly that. It's a cornerstone in modern chemistry, pharmaceutical research, and even in the food and beverage industry. We've designed our equipment to meet these diverse needs, ensuring high performance and durability for labs all over the world. We are proud to bring this technology directly from our factory to your lab, focusing solely on international markets to give you the best.

How Does a Rotary Evaporator Actually Work for Distillation?

Confused by how a rotovap achieves such efficient distillation? The spinning flask and vacuum can seem complex. Understanding its mechanics reveals a simple yet powerful process for solvent separation.

A rotary evaporator works by increasing the sample's surface area through flask rotation. It also lowers the solvent's boiling point using a vacuum. This allows for gentle, rapid evaporation and efficient solvent recovery.

Let me break down how this fantastic piece of equipment operates. We've spent years perfecting these machines, so I know them inside out. The magic of a rotary evaporator lies in a few key principles working together seamlessly.

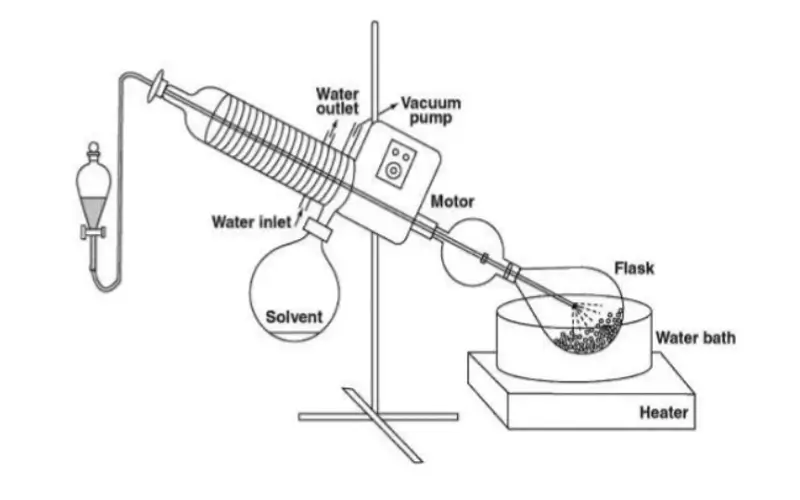

The Core Components and Their Roles

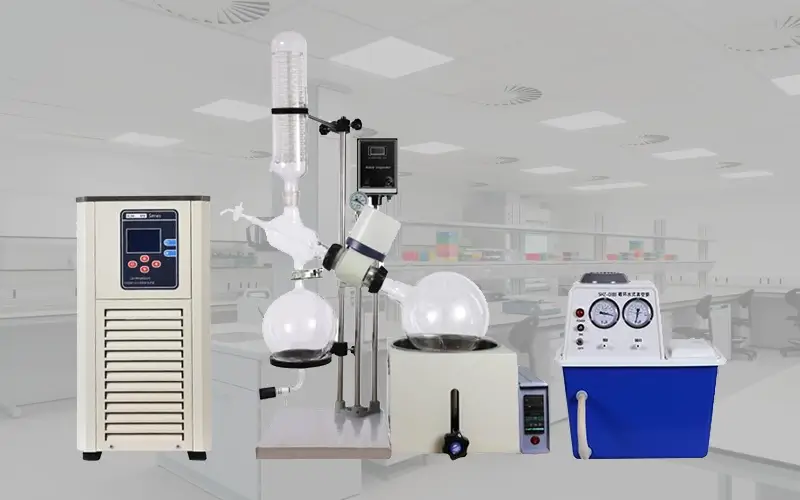

First, you have the evaporating flask. This is where you put your sample. It's gently rotated by a motor, which is super important. This rotation spreads your sample into a thin film on the inner surface of the flask. Think of it like spreading butter on toast – more surface area means faster evaporation. This flask is partially submerged in a heated water or oil bath. This bath provides controlled heat to encourage evaporation. Then, there's the vacuum system. This is critical. By reducing the pressure inside the system, we lower the boiling point of your solvent. This means you can evaporate solvents at lower temperatures, which is a lifesaver for heat-sensitive compounds. Finally, the evaporated solvent vapor travels into a condenser. Here, cooling coils (usually with circulating cold water or a chiller) turn the vapor back into a liquid, which is then collected in a receiving flask. It's a closed system, so you recover your solvent efficiently. I remember when we first started exporting, a client was amazed at how much solvent they could recover and reuse, saving them a lot of money.

The Science Behind It: Evaporation Principles

The core science is quite elegant. Lowering the pressure dramatically reduces the temperature needed to boil a solvent. For example, water boils at 100°C at atmospheric pressure, but under a vacuum, it can boil at room temperature or even lower. The continuous rotation constantly renews the surface film of the liquid, preventing bumping and ensuring even heat distribution. This thin film has a much larger surface area compared to a static pool of liquid, greatly speeding up the evaporation rate. It's a far cry from old-school distillation setups that were slow and often led to sample degradation from overheating.

Step-by-Step Process Walkthrough

Imagine you have a solution you want to concentrate. You'd pour it into the evaporating flask, attach it to the rotovap. You'd start the rotation, turn on the vacuum pump, and set the heating bath to the desired temperature. As the flask rotates and heats gently, the solvent starts to evaporate. You'll see the vapor travel to the condenser, where it liquefies and drips into the collection flask. It's a continuous and relatively quick process. We always guide our new customers through this, and they pick it up very fast.

What Key Factors Should You Consider When Choosing a Rotary Evaporator?

Overwhelmed by the options when buying a rotary evaporator? Choosing the wrong one can waste money and hinder your work. Let's clarify the essential features for your specific needs.

Key factors include flask size, vacuum control, bath temperature range, condenser type, rotation speed, and safety features. Consider your applications and sample types to make the best choice for your lab.

Choosing the right rotary evaporator is something we help our customers with every day. It's not just about getting any machine; it's about getting the right tool for your job. Here’s what I always tell people to think about:

Matching Capacity to Your Needs

How much sample do you typically work with? Our rotary evaporators come with flask sizes ranging from small 0.5L units, perfect for research and development, up to 50L or even 100L systems for pilot-scale or industrial production. If you mostly handle small batches, a 1L or 2L system might be perfect. But if you're processing larger volumes, like in botanical extraction, you’ll need a bigger unit. We ensure our range covers all these scenarios.

Vacuum Precision: The Heart of Efficiency

The vacuum system is the soul of the rotovap. You need good control over the vacuum level to optimize evaporation for different solvents. Some of our models offer simple manual control, which is fine for basic tasks. However, for more sensitive work or when dealing with mixed solvents, a digital vacuum controller that can maintain a precise vacuum level or even run programmed ramps is invaluable. We've found that stable vacuum significantly improves reproducibility.

Temperature Control: Protecting Your Samples

The heating bath needs to provide accurate and stable temperature. Most of our units use a water bath, which is great for temperatures up to 99°C. For solvents with higher boiling points, an oil bath option is available, extending the range typically up to 180°C or higher. Over-temperature protection is a standard safety feature we include, because protecting your sample (and your lab!) is paramount.

Condenser Design: Maximizing Recovery

The condenser's job is to trap all your evaporated solvent. We offer different designs: diagonal condensers are common for standard distillations, while vertical condensers save space. For very low-boiling solvents or when using tap water that isn't very cold, a cold finger condenser or a more efficient coiled condenser paired with a recirculating chiller is a better choice. We can help you pick the one that gives you the best recovery rate for your specific solvents. We even have options for dual condensers for really high recovery rates.

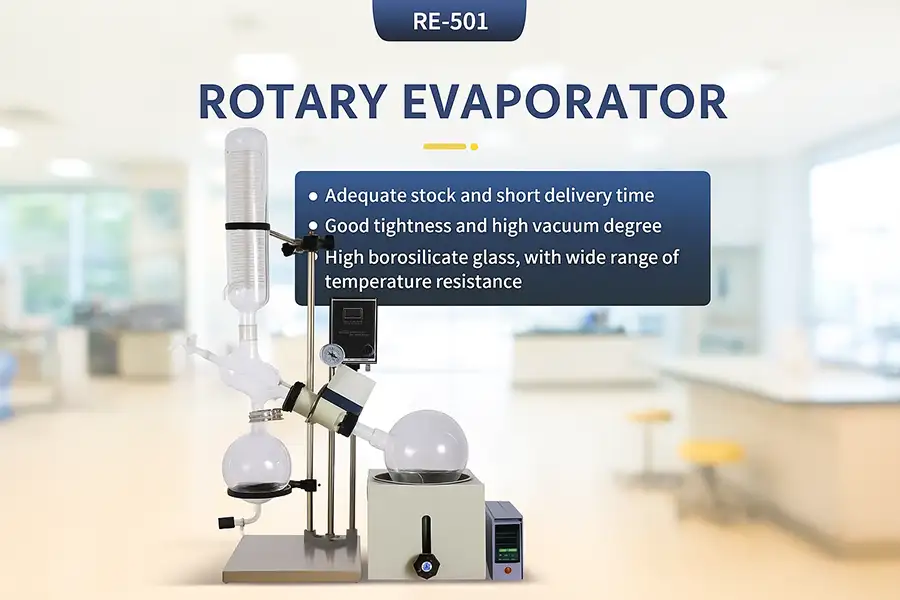

Safety First: Essential Features

Safety is non-negotiable in any lab. Our rotary evaporators are designed with features like motorized lifts to easily raise the flask from the hot bath in case of a power outage or if the process needs to be stopped quickly. Coated glassware is also an option we offer for added protection against breakage and spillage. We hold ISO9001 and CE certificates, which shows our commitment to quality and safety in our manufacturing.

| Feature | Small Research Lab Focus | Pilot Scale / Production Focus |

|---|---|---|

| Evaporating Flask Size | 0.5L - 5L | 10L - 50L (or larger) |

| Vacuum Control | Manual or basic digital | Advanced digital with programming, integrated pump control |

| Lift Mechanism | Manual or simple motorized | Heavy-duty motorized, often with safety stop |

| Glassware | Standard borosilicate | Thicker glass, optional coating, explosion-proof options |

| Automation | Minimal | Options for continuous feed, automatic draining |

I recall a client from a university research lab. They were working with very delicate compounds. We spent quite a bit of time discussing their needs and ended up customizing a smaller unit with very precise vacuum and temperature control. They were thrilled with the results, and it makes us proud to contribute to their research. This is why understanding these factors is so vital. We are not just selling a machine; we are providing a solution.

What Are the Common Applications of Rotary Evaporator Distillation Across Industries?

Wondering if a rotary evaporator is right for your specific field? Its versatility might surprise you. This instrument is a true workhorse in many different scientific and industrial sectors.

Rotary evaporators are widely used in chemical synthesis, pharmaceutical research for drug discovery. Also in food and beverage for flavor extraction, environmental analysis for sample concentration, and cannabis processing.

It's always amazing to see the wide range of industries that rely on rotary evaporators. As a manufacturer who has been exporting these for over 16 years to 87 countries, we've seen it all. This isn't just a piece of chemistry lab equipment; it's a core tool for innovation everywhere.

Pharmaceuticals and Biotechnology: Gentle Concentration

In pharma and biotech, researchers are often working with precious, heat-sensitive compounds. Think about developing new medicines or isolating active pharmaceutical ingredients (APIs). A rotary evaporator is perfect because it can remove solvents at low temperatures, preventing degradation of these delicate molecules. We've supplied units for peptide purification, natural product extraction from plants, and for concentrating reaction mixtures during drug synthesis. The gentle handling is key.

Chemical Research: Synthesis and Purification

For chemists, a rotovap is a daily workhorse. After synthesizing a new compound, they need to remove solvents from the reaction mixture. It's also used for recrystallization, drying powders, and recycling solvents, which is both economical and environmentally friendly. I remember my own days in the lab; the rotovap was always busy! Our robust designs can handle a wide variety of chemicals, which is essential in a research setting.

Food and Beverage: Flavor and Aroma Crafting

This is a fun one! The food and beverage industry uses rotary evaporators for extracting delicate flavors and aromas from herbs, spices, fruits, and flowers. Imagine creating concentrated fruit juices without "cooking" away the fresh taste, or producing high-quality essential oils. It's also used in molecular gastronomy to create unique culinary experiences. We have clients using our equipment to make amazing coffee extracts and craft spirits.

Environmental Science: Sample Preparation

When environmental labs test for pollutants in water or soil, those pollutants are often present in very tiny amounts. Rotary evaporators help by concentrating these samples before analysis. This makes it easier to detect and quantify contaminants. It’s a crucial step in ensuring environmental safety. We're proud that our equipment contributes to this important work.

Cannabis and Hemp Processing: Extract Refinement

The cannabis and hemp industry has become a significant user of rotary evaporators. After extracting cannabinoids like THC and CBD using solvents like ethanol, the rotovap is essential for recovering that ethanol. It’s also used for further purification and distillation of the extracts to achieve high purity. We've adapted some of our larger models specifically for the needs of this rapidly growing industry, focusing on efficiency and safety.

Examples of materials processed with our equipment:

Active Pharmaceutical Ingredients (APIs)

Natural plant extracts for medicines and supplements

Synthesized organic and inorganic compounds

Essential oils, fragrances, and food flavorings

Cannabinoid oils (CBD, THC)

Environmental samples for trace analysis

We've seen our instruments used for everything from academic research at universities to full-scale production in factories. Each application has its unique challenges, and we've learned so much by working closely with our clients to provide them with the best possible equipment solutions. It’s a testament to the versatility of rotary evaporator technology.

Conclusion

Rotary evaporator distillation is vital and versatile. Understanding its work, selection, and uses helps you optimize lab processes and achieve better results with our reliable equipment.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

What Is a Rotary Evaporator? Beginner-Friendly Guide to Rotary Evaporation

Learn what a rotary evaporator is, how it works, and how it solves common solvent removal problems in laboratories and production. Clear, beginner-friendly ex...

Read MoreHow Do Rotary Evaporators Work? A Practical, Easy Guide for Faster Solvent Removal

Learn how rotary evaporators work in plain English: vacuum + gentle heating + rotation + condensation. See key specs (2L–50L) and how to choose the right rota...

Read MoreRotovap Distillation | Complete Guide to Rotary Evaporators

Learn everything about rotovap distillation, how rotary evaporators work, applications in chemical labs, and why they are essential for efficient solvent remo...

Read More