What Exactly is a Rotary Evaporator?

Picture this: You've spent hours perfecting a delicate botanical extract, and now you need to remove the solvent without damaging those precious compounds. Enter the rotary evaporator - or "rotovap" as lab folks affectionately call it.

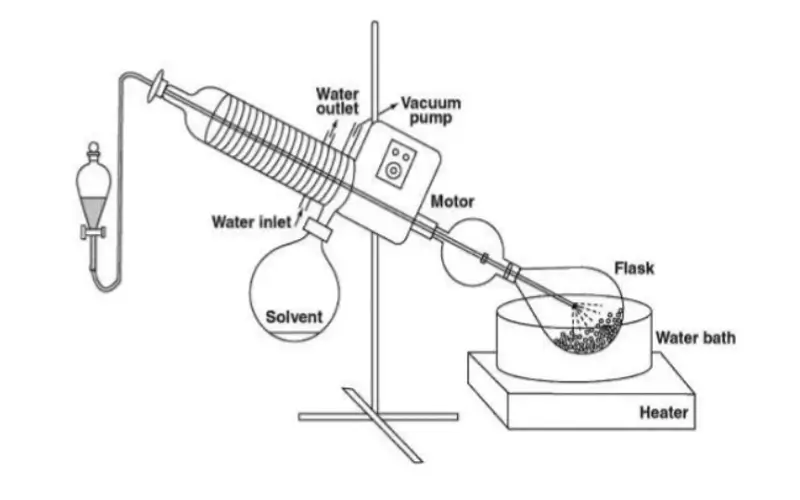

A benchtop rotary evaporator is essentially a sophisticated distillation system designed for gentle solvent removal. Its magic lies in three key components:

Rotating Flask

Creates a thin solvent film for rapid evaporation

Temperature Control

Heating bath for controlled evaporation

Vacuum System

Lowers boiling points for gentle processing

A modern benchtop rotary evaporator setup with key components labeled

How does a rotary evaporator differ from simple distillation?

Great question! While both techniques separate solvents, rotary evaporation works under vacuum conditions which dramatically lowers boiling points. This means you can evaporate solvents at much lower temperatures - critical when working with heat-sensitive compounds like essential oils or pharmaceuticals. The rotating flask also creates a larger surface area, speeding up evaporation by 3-5 times compared to standard distillation.

Why Benchtop Models are Stealing the Spotlight

Full-sized rotovaps have been lab staples for decades, but benchtop rotary evaporators are causing a scientific sensation. Here's why:

Space Savers Extraordinaire

With lab real estate at a premium, these compact units can fit where traditional models can't - perfect for crowded labs or mobile research stations.

Energy Efficiency Champions

Smaller size means 30-40% less energy consumption. A study by the Green Labs Initiative found benchtop models reduce energy costs by $300-500 annually per unit.

Surprising Capacity

Don't let size fool you! Modern benchtop units handle 2L to 5L volumes with ease - perfect for most R&D and small-batch production needs.

Budget Friendly Science

Typically 20-40% less expensive than full-sized counterparts, benchtop rotovaps deliver professional results without the professional price tag.

Pro Tip

For solvent recovery applications, choose a model with a high condensation efficiency rating. According to MIT's Sustainable Labs Project, efficient condensers can recover up to 95% of solvents, potentially saving labs over $15,000 annually in solvent costs per unit.

Are benchtop rotary evaporators suitable for industrial applications?

While traditionally seen as research tools, modern benchtop models are increasingly used in pilot plants and small-scale production. With capacities up to 10L and advanced automation features, they're perfect for process development, quality control testing, and low-volume specialty chemical production. For continuous large-scale operations, dedicated large scale rotary evaporators remain the optimal choice.

Choosing Your Perfect Benchtop Partner

Not all benchtop rotovaps are created equal. Consider these factors when selecting your lab's new MVP:

Match capacity to your typical batch sizes

According to Lab Manager Magazine survey

Modern units vs. older models (OSHA data)

Popular Benchtop Solutions

RE-201D 2L Rotary Evaporator

Perfect for small-scale research and teaching labs. Features digital controls and a space-saving design.

2L evaporation flask

Digital temperature control

Auto lift function

RE-501 5L Rotary Evaporator

The sweet spot between capacity and footprint. Ideal for pilot studies and medium-volume applications.

5L evaporation flask

Programmable operation

Advanced safety features

E-2000ABE Mini Rotary Evaporator

Ultra-compact solution for micro-extractions and space-constrained environments.

500ml-1000ml capacity

Integrated vacuum system

Portable design

What maintenance does a rotary evaporator require?

Regular maintenance ensures longevity and consistent performance. Monthly tasks include cleaning condensation coils, checking vacuum seals, and lubricating moving parts. Always consult your rotary evaporator manual for specific maintenance schedules. Pro tip: Keep a maintenance log - labs that document maintenance experience 30% fewer unexpected breakdowns according to Journal of Lab Automation studies.

The Economic Advantage: Saving Money Never Looked So Scientific

Let's talk numbers - the real language of lab managers! While benchtop rotary evaporators require an initial investment, their economic benefits are compelling:

Solvent Recovery: Recover 80-95% of expensive solvents for reuse

Time Savings: Process samples 3x faster than traditional methods

Energy Efficiency: Use 30-40% less energy than full-sized units

Reduced Waste: Minimize disposal costs with efficient recovery

"Laboratories using modern rotary evaporators report an average ROI of 14 months, primarily through solvent savings and increased productivity." - Lab Economics Quarterly

Future-Proof Your Lab

With the rise of sustainable science practices, solvent recovery isn't just economical - it's becoming an environmental imperative. The EPA's Green Chemistry Program notes that solvent use accounts for nearly 60% of industrial waste. By implementing efficient rotary evaporation, labs reduce their environmental footprint while boosting their bottom line.

Ready to Transform Your Lab?

Explore our range of precision benchtop rotary evaporators designed for modern laboratories