Explosion Proof Rotary Evaporators: Your Lab's Safety Guardian

Discover the crucial safety technology that's revolutionizing solvent handling in laboratories worldwide

Picture this: You're concentrating a batch of valuable pharmaceutical compounds using ethanol as your solvent. The process is running smoothly until suddenly - a spark ignites the solvent vapors. This nightmare scenario is why explosion proof rotary evaporators aren't just equipment; they're your first line of defense.

Rotary evaporators ("rotovaps") are essential in labs for gentle solvent removal, but traditional models carry hidden dangers when working with flammable solvents. Explosion proof rotary evaporators solve this critical safety challenge with specialized engineering that prevents ignition sources from contacting volatile vapors.

What's the most common cause of lab explosions involving rotary evaporators?

Answer: The primary cause is electrical sparks from standard motors and switches igniting flammable solvent vapors. This risk is especially high with low-boiling-point solvents like diethyl ether, hexane, and acetone that create explosive atmospheres at room temperature.

In this comprehensive guide, we'll explore why explosion proof technology is non-negotiable for modern labs, how these specialized rotovaps work, and what features to look for when investing in lab safety.

Why Explosion Proof Technology Is Non-Negotiable

The Hidden Danger in Every Lab

Standard rotary evaporators have multiple potential ignition sources: the motor, electrical switches, and heating bath. When flammable solvent vapors accumulate - which they inevitably do during evaporation - you're essentially creating a potential bomb in your lab.

According to the U.S. Chemical Safety Board, solvent-related fires and explosions account for 21% of all laboratory accidents, with rotary evaporators being a frequent culprit due to their extensive solvent-handling capabilities.

How Explosion Proof Design Solves the Problem

Explosion proof rotary evaporators eliminate ignition risks through three critical engineering solutions:

Spark-proof motors enclosed in sealed casings

Intrinsically safe electrical systems that limit energy to non-ignition levels

Vapor-tight enclosures preventing solvent vapors from contacting electrical components

These designs meet stringent international standards like ATEX and IECEx, ensuring they can safely handle Category 1 flammable substances.

Can explosion proof rotary evaporators handle all types of flammable solvents?

Answer: While they're designed for most common lab solvents, always check the specific classification. Explosion proof models are rated for different explosive atmospheres based on solvent flash points and vapor concentrations. For example, our RE-501 5L rotary evaporator is certified for solvents with flash points as low as -20°C, covering ethanol, methanol, acetone, and hexane.

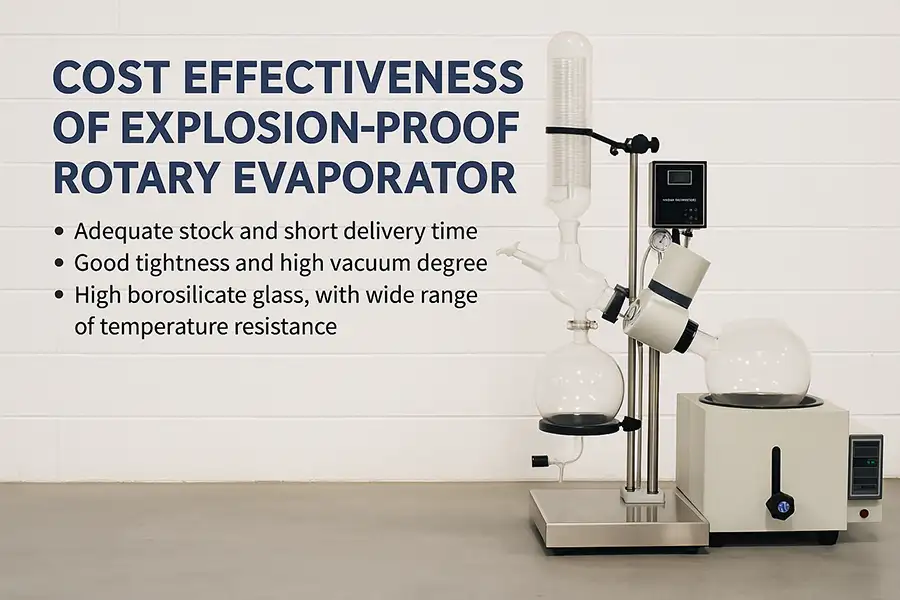

Saving Money Is The Last Word, And It Is Worth Investing In Buying!

Many lab managers hesitate at the 20-30% premium for explosion proof models, but consider this: The average laboratory fire causes $150,000 in direct damages according to NFPA research, not including:

Days of lab downtime after a fire incident

Average insurance premium increase post-accident

Of solvent-related accidents cause injuries

When you consider these numbers, explosion proof rotary evaporators aren't an expense - they're one of the smartest investments in lab safety and operational continuity you can make.

Find Your Lab's Perfect Safety Partner

Explore our range of explosion proof rotary evaporators for every application

Compact Workhorses

Perfect for research labs and small-batch processing:

Ideal for precious samples and solvent screening

Space-saving designs without compromising safety

Perfect for educational institutions

Mid-size Performers

The sweet spot for most laboratory applications:

Balance capacity and footprint

Handle daily solvent removal tasks

Perfect for pilot plant operations

Industrial Scale Solutions

For production environments and large-volume processing:

Robust construction for continuous operation

High evaporation capacity

Automation-ready designs

Can explosion proof rotary evaporators be automated?

Answer: Absolutely! Modern explosion proof models like our RE-2002 rotary evaporator machine offer full automation capabilities with programmable settings, automatic lifting, and solvent recovery integration - all within explosion proof parameters. Automation actually enhances safety by reducing operator exposure during evaporation processes.

Ready to Transform Your Lab's Safety?

Join thousands of laboratories that have made the smart switch to explosion proof technology

Safety Doesn't Happen By Accident

In the high-stakes world of laboratory operations, explosion proof rotary evaporators represent more than just equipment - they embody a commitment to safety culture. By investing in these specialized rotovaps, you're not just preventing potential disasters; you're creating an environment where researchers can focus on discovery rather than danger.

Remember the words of safety pioneer Paul O'Neill: "If you think safety is expensive, try having an accident." With explosion proof technology, you're paying a small premium today to avoid catastrophic costs tomorrow. Whether you need a compact mini rotary evaporator for research or an industrial-scale 20L rotary evaporator for production, there's an explosion proof solution that fits your lab's needs

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

Rotary Evaporator Machine - Complete Guide

Comprehensive guide to rotary evaporator machines covering working principles, components, applications, technical specs, and tips for selecting the right mod...

Read MoreEthanol Rotary Evaporator Guide

Discover how ethanol rotary evaporators work, their cost-saving benefits, and how to choose the right model. Learn solvent recovery techniques, safety practic...

Read MoreBenchtop Rotary Evaporator: Your Lab's Solvent-Saving Superhero

Discover how benchtop rotary evaporators revolutionize solvent recovery in labs. Learn space-saving benefits, cost efficiency, and how to choose the perfect m...

Read More