Ethanol Rotary Evaporator: Your Solvent Recovery Powerhouse

Discover how this ingenious lab equipment saves time, money, and the environment while purifying your ethanol solutions

Ever wonder how scientists and manufacturers efficiently separate ethanol from valuable compounds without degrading them? Enter the rotary evaporator (affectionately known as "rotovap") - the unsung hero of laboratories and production facilities worldwide.

Rotary evaporators are essential for anyone working with ethanol extraction, from cannabis oil producers to pharmaceutical researchers. These ingenious devices harness the power of controlled evaporation to gently remove solvents like ethanol while preserving delicate compounds.

Rotary evaporators provide precise control over solvent removal processes

In this comprehensive guide, we'll explore why ethanol rotary evaporators have become the gold standard in solvent recovery, how they outperform traditional methods, and what features to consider when choosing your perfect ethanol extraction partner.

The Magic Behind Rotary Evaporation

How does a rotary evaporator manage to separate ethanol so efficiently?

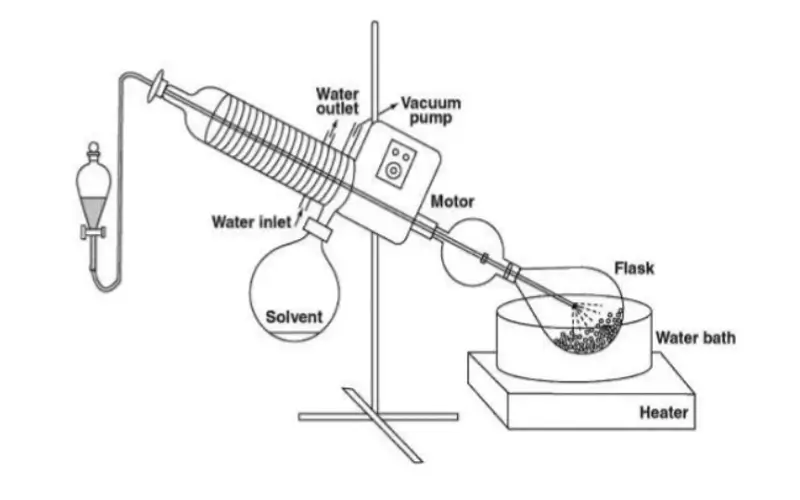

The secret lies in three clever principles working in harmony:

Rotation: The flask rotates, creating a thin film of solution that dramatically increases surface area

Reduced Pressure: A vacuum pump lowers pressure, reducing ethanol's boiling point from 78°C to as low as 20°C

Controlled Heating: A water bath gently heats the solution without damaging sensitive compounds

This triple-threat approach means you can evaporate ethanol quickly at low temperatures, preserving your valuable extracts.

Imagine trying to dry a wet towel. If you lay it flat (like traditional evaporation), it takes forever. But if you spin it (like the rotating flask), the water flies off much faster. That's essentially what a rotovap does with ethanol!

Key components of a rotary evaporator system

Why Ethanol Reigns Supreme in Extraction

Ethanol isn't just for your Friday night cocktails - it's a superstar solvent in laboratories and extraction facilities. Here's why it's the go-to choice:

With proper rotovap systems

By the FDA for food and pharmaceutical use

Ethanol's unique properties make it ideal for botanical extractions, pharmaceutical purification, and cannabis processing:

Polarity Power: Effectively extracts both water-soluble and oil-soluble compounds

Low Toxicity: Safer for operators and the environment compared to alternatives

Easy Removal: Relatively low boiling point makes recovery efficient

Regulatory Friendly: Widely approved for food, pharmaceutical, and cosmetic applications

According to the American Chemical Society, laboratories implementing ethanol recovery systems reduce solvent costs by 60-80% annually while decreasing environmental impact.

Saving Money Is The Last Word, And It Is Worth Investing In Buying!

Let's talk numbers - because in business and research, ROI matters. While quality rotary evaporators require upfront investment, they quickly pay for themselves through:

How much can I actually save with an ethanol rotary evaporator?

Consider this real-world example: A mid-sized CBD extraction facility processing 100L of ethanol solution weekly:

Without recovery: $1,200/week in ethanol costs

With 85% recovery: $180/week in ethanol costs

That's over $50,000 saved annually - enough to pay for a premium rotovap system several times over! Most facilities recoup their investment in 3-6 months.

Solvent Recovery

Reclaim 80-95% of ethanol for reuse

Energy Efficiency

Low-temperature operation reduces energy costs

Time Savings

Process large volumes 3-5x faster than alternatives

Finding Your Perfect Ethanol Extraction Partner

Not all rotary evaporators are created equal. Choosing the right system depends on your specific needs:

What size rotary evaporator is right for my application?

Capacity matters! Here's a quick guide:

Research & Development: 2L-5L systems

Pilot Scale Production: 10L-20L systems

Commercial Extraction: 50L systems

Consider both your current needs and future growth. Many facilities start with a mid-sized unit and scale up as production increases.

Compact 2L Rotary Evaporator

Ideal for research labs and small-batch processing. Features precise digital controls and space-saving design.

Perfect for method development

Energy-efficient operation

Easy to clean and maintain

Versatile 5L Rotary Evaporator

The workhorse of many laboratories. Balances capacity with flexibility for diverse applications.

Ideal for pilot-scale production

Enhanced safety features

Compatible with various solvents

High-Capacity 10L System

Designed for commercial production environments. Handles larger volumes with industrial durability.

Automated controls for consistency

Rapid ethanol recovery

Built for continuous operation

Industrial 50L Rotary Evaporator

The solution for large-scale ethanol recovery. Maximizes throughput for high-volume facilities.

Heavy-duty construction

Advanced automation features

Optimized for ethanol recovery

Safety First: Working With Ethanol

Ethanol is flammable and requires careful handling. Follow these essential safety practices:

Critical Safety Measures

Always use explosion-proof equipment in areas with ethanol vapors

Ensure proper ventilation in your workspace

Never bypass safety interlocks or pressure relief valves

Use secondary containment for ethanol collection vessels

Implement strict no-open-flame policies in extraction areas

According to the National Fire Protection Association, proper solvent handling procedures reduce laboratory fire incidents by 72%. Don't cut corners when working with ethanol - your safety and facility depend on it.

Modern rotovaps include multiple safety features for ethanol processing

The Future of Ethanol Extraction

Rotary evaporation technology continues to evolve with exciting advancements:

With next-gen vacuum systems

Smart systems adapting in real-time

According to MIT's Chemical Engineering Department, AI integration in evaporation systems will increase ethanol recovery efficiency by 25-40% by 2028 while reducing energy consumption.

Whether you're extracting precious cannabinoids, purifying pharmaceutical compounds, or recovering botanical extracts, ethanol rotary evaporators deliver unparalleled efficiency, quality, and cost savings. Investing in the right system isn't an expense - it's a profit center that pays dividends for years to come.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

Rotary Evaporator Machine - Complete Guide

Comprehensive guide to rotary evaporator machines covering working principles, components, applications, technical specs, and tips for selecting the right mod...

Read MoreExplosion Proof Rotary Evaporator - Your Lab's Safety Guardian

Discover why explosion proof rotary evaporators are essential lab safety equipment. Learn how they prevent solvent fires, save costs long-term, and explore mo...

Read MoreBenchtop Rotary Evaporator: Your Lab's Solvent-Saving Superhero

Discover how benchtop rotary evaporators revolutionize solvent recovery in labs. Learn space-saving benefits, cost efficiency, and how to choose the perfect m...

Read More