Rotary Evaporator Machine: A Complete Guide

Everything you need to know about rotary evaporators - from working principles to selecting the perfect model for your laboratory or industrial application

What is a Rotary Evaporator Machine?

A rotary evaporator machine is an essential laboratory device used for the efficient and gentle removal of solvents from samples by evaporation. This sophisticated instrument plays a vital role in many scientific domains due to its unique capabilities.

Key characteristics:

Operates under reduced pressure to lower solvent boiling points

Preserves heat-sensitive compounds by using lower temperatures

Uses rotation to enhance evaporation efficiency

Features automated controls for precision processing

Allows solvent recovery for cost efficiency and environmental benefits

How Does a Rotary Evaporator Work?

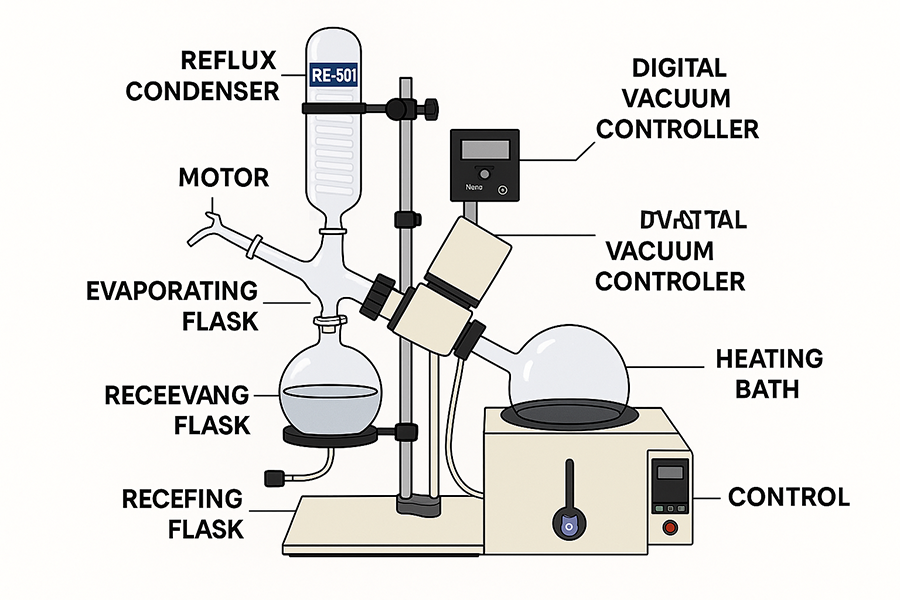

The rotary evaporator consists of several critical components working in harmony:

Motor & Rotation System

Rotates the evaporation flask, increasing surface area and preventing bumping. Rotation speeds typically range from 20-280 RPM.

Heating Bath

Provides controlled thermal energy to the rotating flask (water or oil bath). Temperature control precision to ±0.5°C.

Vacuum System

Lowers pressure to reduce boiling points. Creates vacuum levels from 10-760 mbar depending on application.

Condenser

Cools vapors to liquid state for collection. Various cooling methods (cold finger, coiled, or Dimroth condensers).

Applications of Rotary Evaporator Machines

Rotary evaporators are versatile instruments with applications across numerous industries:

Chemical & Research Labs

Solvent Removal

Compound Purification

Distillation Processes

Sample Concentration

Pharmaceutical Industry

API Extraction

Drug Formulation

Solvent Recycling

Purification Processes

Food & Beverage

Flavor Concentration

Decaffeination

Alcohol Removal

Essential Oil Extraction

Environmental Analysis

Sample Preparation

Solvent Recovery

Waste Treatment

Analytical Concentration

Choosing the Right Rotary Evaporator Machine

Selecting the optimal rotary evaporator requires careful consideration of several factors:

Small-Scale Laboratory

2L Rotary Evaporator

Ideal for:

Research laboratories

Academic institutions

Small batch processing

Budget-conscious setups

Mid-Scale Laboratory

5L Rotary Evaporator

Ideal for:

R&D departments

Pilot plants

Pharmaceutical testing labs

Medium production

Industrial Production

50L Rotary Evaporator

Ideal for:

Large-scale production

Industrial chemical plants

Pharmaceutical manufacturing

Continuous processing

Spatial requirements: Larger units need more lab space and supporting infrastructure

Operating costs: Increased energy consumption and higher solvent requirements

Sample considerations: Larger flask sizes may be inappropriate for valuable samples

Precision: Some processes require smaller setups for better thermal control

Technical Specifications and Comparison

Selecting based on specifications:

| Model | Capacity | Bath Temp Range | Vacuum Level | Typical Batch Size | Rotation Speed |

|---|---|---|---|---|---|

| RE-201D | 2 Liters | RT - 99°C | Up to 399 Pa | 50 ml - 1.5L | 20-280 RPM |

| RE-501 | 5 Liters | RT - 99°C | Up to 399 Pa | 200ml - 4L | 20-250 RPM |

| RE-1050 | 50 Liters | RT - 180°C | Up to 133 Pa | 5L - 45L | 20-200 RPM |

Future Trends in Rotary Evaporation

Current innovations are transforming rotary evaporation technology:

Automated systems: Full process integration with programmable automation

Advanced controls: Touchscreen interfaces with recipe storage

Remote monitoring: IoT connectivity for wireless operation oversight

AI integration: Intelligent systems that learn from historical data

Green technology: Reduced energy designs with higher solvent recovery rates

Modular designs: Configurable systems with swappable components

Complex decision-making in non-standard situations

Equipment troubleshooting and maintenance oversight

Experimental design based on scientific intuition

Ensuring quality control and regulatory compliance

Adapting protocols during experimental anomalies

Conclusion

Rotary evaporator machines form the backbone of countless laboratory processes across research and industry. Their gentle solvent removal capabilities make them invaluable for sample preparation and material purification.

Understanding the fundamental operational principles and carefully matching equipment specifications to your application's requirements ensures optimal performance and value. From compact 2L systems for academic research to industrial-scale 50L units for manufacturing, a well-chosen rotary evaporator delivers exceptional efficiency gains and reproducibility.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

Explosion Proof Rotary Evaporator - Your Lab's Safety Guardian

Discover why explosion proof rotary evaporators are essential lab safety equipment. Learn how they prevent solvent fires, save costs long-term, and explore mo...

Read MoreEthanol Rotary Evaporator Guide

Discover how ethanol rotary evaporators work, their cost-saving benefits, and how to choose the right model. Learn solvent recovery techniques, safety practic...

Read MoreBenchtop Rotary Evaporator: Your Lab's Solvent-Saving Superhero

Discover how benchtop rotary evaporators revolutionize solvent recovery in labs. Learn space-saving benefits, cost efficiency, and how to choose the perfect m...

Read More