How Does a Rotovap Work? A Simple Guide to Rotary Evaporators

If you work in a lab, research facility, or industrial setting, you’ve probably heard of a rotary evaporator—or rotovap for short. But how exactly does this essential piece of lab equipment work? Why is it so widely used in chemistry, pharmaceuticals, food science, and more? And what should you consider when choosing one for your lab?

In this beginner-friendly guide, we’ll break down everything you need to know about rotary evaporators. By the end, you’ll understand their key components, how they operate, their advantages, and how to pick the right model for your needs. Let’s dive in!

What Is a Rotary Evaporator (Rotovap)?

A rotary evaporator is a device used to gently and efficiently remove solvents from liquid mixtures. Think of it as a “smart distillation machine” that helps scientists separate solvents (like water, alcohol, or acetone) from temperature-sensitive compounds without damaging them.

Common uses include:

Concentrating solutions (e.g., extracting flavors from fruit).

Purifying compounds (e.g., isolating active ingredients in medicines).

Recycling solvents for reuse.

Rotovaps are especially popular in organic chemistry, pharmaceutical labs, and industries that work with essential oils, cannabis extracts, or food additives.

How Does a Rotovap Work? The Step-by-Step Process

Let’s simplify how a rotary evaporator works into five easy steps:

1. Lowering the Boiling Point with Vacuum

Solvents boil when their vapor pressure equals atmospheric pressure. But under normal conditions, many solvents boil at high temperatures that could damage delicate compounds.

A rotovap solves this by reducing the pressure inside the system using a vacuum pump. Lower pressure = lower boiling point. For example, water boils at 100°C at sea level but can boil at just 40°C in a strong vacuum. This gentle heating protects heat-sensitive materials.

2. Rotating the Flask for Faster Evaporation

The sample is placed in a rotating flask (hence the name “rotary” evaporator). Spinning the flask creates a thin film of liquid on the inner surface, increasing the area exposed to heat. This speeds up evaporation without needing extreme temperatures.

3. Heating the Sample (Carefully)

A heated water or oil bath warms the rotating flask. Since the solvent’s boiling point is already lowered by the vacuum, only mild heat is needed. This combination of low pressure and gentle heat ensures efficient evaporation.

4. Condensing the Vapor Back to Liquid

The evaporated solvent travels into a condenser, where it’s cooled (usually by circulating coolant) and turns back into liquid. This liquid is collected in a separate flask, leaving behind the concentrated sample.

5. Automating the Process

Modern rotovaps often include timers, digital controls, and safety features to automate the process. Users can set parameters like rotation speed, temperature, and vacuum strength for consistent results.

Key Components of a Rotary Evaporator

To fully understand how a rotovap works, let’s look at its main parts:

Motor Unit: Rotates the evaporation flask.

Evaporation Flask: Holds the sample and spins to spread it into a thin film.

Heating Bath: Gently warms the flask (water or silicone oil).

Condenser: Cools vapor back into liquid. Common types include coiled or vertical condensers.

Vacuum Pump: Reduces pressure in the system.

Receiving Flask: Collects the condensed solvent.

Control Panel: Adjusts rotation speed, temperature, and vacuum.

Higher-end models may also include:

Automatic lifting mechanisms to raise/lower the flask.

Cold traps for better solvent recovery.

Software for data logging.

Why Use a Rotary Evaporator? Key Advantages

Rotovaps are a staple in labs worldwide—and for good reason. Here’s why they’re preferred over simple distillation setups:

Gentle on Sensitive Materials

By combining low pressure and controlled heat, rotovaps prevent thermal degradation of compounds like proteins, natural extracts, or pharmaceuticals.Faster than Traditional Methods

The rotating flask increases evaporation speed, saving hours compared to air-drying or basic distillation.Solvent Recovery

Reclaim and reuse expensive solvents, reducing costs and environmental impact.Scalability

Rotovaps come in sizes from small benchtop units to large industrial systems, handling volumes from milliliters to liters.User-Friendly

Modern models are easy to operate, even for beginners.

Common Applications of Rotary Evaporators

Rotovaps are versatile tools. Here are some real-world examples of how they’re used:

Pharmaceuticals: Isolating pure drug compounds from reaction mixtures.

Food & Beverage: Concentrating flavors (e.g., vanilla extract) or removing alcohol from wines.

Cannabis Industry: Extracting CBD or THC oils.

Research Labs: Purifying chemicals for experiments.

Environmental Testing: Concentrating water samples to detect pollutants.

How to Choose the Right Rotary Evaporator

With so many models on the market, picking the right rotovap can be overwhelming. Here’s what to consider:

1. Capacity

Choose a flask size that matches your typical sample volume. Small labs might use 1–5L flasks, while production facilities may need 20L+ systems.

2. Vacuum Performance

A stronger vacuum pump allows lower pressure, which is critical for high-boiling-point solvents like water.

3. Temperature Range

Ensure the heating bath can reach the temperatures your solvents require under reduced pressure.

4. Build Quality

Look for corrosion-resistant materials (e.g., glass, PTFE) if working with aggressive chemicals.

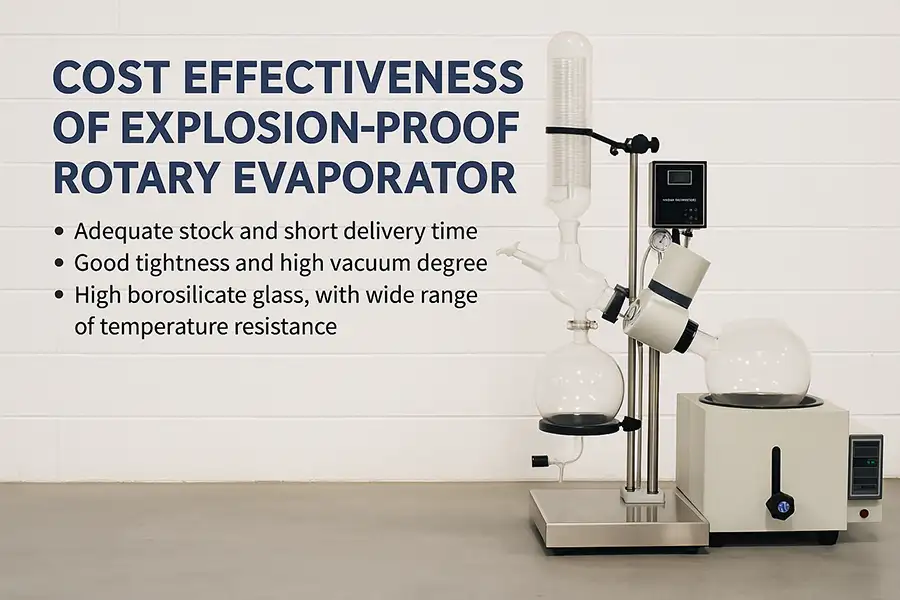

5. Safety Features

Auto-lift functions, overheat protection, and explosion-proof designs are vital for handling flammable solvents.

6. Budget

Balance cost with long-term needs. Cheaper models may lack durability or advanced features.

Rotovap Maintenance Tips

To keep your rotary evaporator running smoothly:

Clean glassware after each use to prevent residue buildup.

Regularly check vacuum pump oil levels.

Inspect seals and O-rings for wear.

Use a cold trap to protect the pump from solvent vapors.

Frequently Asked Questions

Q: Can a rotovap handle high-viscosity samples?

A: Yes, but slower rotation speeds may be needed to spread thick liquids evenly.

Q: Is it safe to use with flammable solvents?

A: Absolutely—just ensure the unit has explosion-proof certifications and proper ventilation.

Q: How do I prevent bumping (sudden boiling)?

A: Use anti-bumping granules or maintain a stable vacuum/temperature.

Q: Can I automate a rotovap?

A: Yes! Many models offer programmable settings for unattended operation.

Why Choose Our Rotary Evaporators?

As a trusted manufacturer and exporter of lab equipment, we specialize in high-performance rotary evaporators designed for reliability, safety, and ease of use. Here’s what sets our rotovaps apart:

Customizable Configurations: Tailor flask sizes, condensers, and pumps to your needs.

Energy-Efficient Design: Save on power and solvent costs.

Global Certifications: Compliant with ISO, CE, and explosion-proof standards.

24/7 Support: Our team is always ready to assist with installation or troubleshooting.

Final Thoughts

Rotary evaporators are indispensable tools for labs and industries that prioritize efficiency, precision, and safety. By understanding how they work—and what features to look for—you can make an informed decision that boosts productivity and saves costs.

Whether you’re distilling essential oils, purifying novel compounds, or recycling solvents, a high-quality rotovap is an investment that pays off in the long run.

Ready to upgrade your lab? [Contact us] today to explore our range of rotary evaporators and find the perfect fit for your application!

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

Rotary Evaporator Machine - Complete Guide

Comprehensive guide to rotary evaporator machines covering working principles, components, applications, technical specs, and tips for selecting the right mod...

Read MoreExplosion Proof Rotary Evaporator - Your Lab's Safety Guardian

Discover why explosion proof rotary evaporators are essential lab safety equipment. Learn how they prevent solvent fires, save costs long-term, and explore mo...

Read MoreEthanol Rotary Evaporator Guide

Discover how ethanol rotary evaporators work, their cost-saving benefits, and how to choose the right model. Learn solvent recovery techniques, safety practic...

Read More