The Complete Guide to Buying a Rotary Evaporator

Maximize Lab Efficiency and Save Costs: Everything You Need to Know Before You Buy Rotovap

Imagine reclaiming valuable solvents without losing any of your precious compounds. Picture reducing evaporation times from hours to minutes. Envision freeing up your lab technicians for more critical tasks. This isn't future tech—it's what a rotary evaporator can do for your lab today.

Rotary evaporators—affectionately known as rotovaps—are the unsung heroes of thousands of laboratories worldwide. From pharmaceutical development to essential oil extraction, cannabis processing to academic research, these remarkable devices revolutionize the way we separate solvent mixtures. And investing in the right one can boost your lab's productivity faster than you might think.

A modern rotary evaporator simplifies solvent separation processes

But how can you tell if you're making the right choice when you buy rotovap equipment? How do you know which features matter most? What size suits your current and future needs? And perhaps most importantly—how can this investment actually save you money when it's a significant capital outlay? Let's evaporate the confusion and distill the answers you need.

The Magic Behind Rotary Evaporation

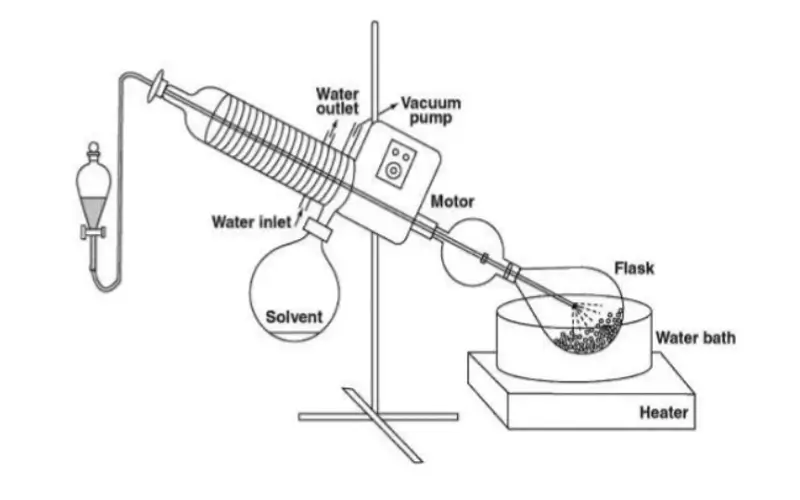

At its core, a rotary evaporator is brilliant in its simplicity:

Rotation: Your solvent mixture rotates in a flask, increasing surface area

Vacuum: Pressure reduction lowers boiling points dramatically

Heating: Gentle warming encourages evaporation under low pressure

Cooling: A condenser efficiently recaptures your solvents

By reducing pressure, a rotovap lowers boiling points significantly. A solvent that normally boils at 78°C like ethanol drops to around 40°C under vacuum—protecting heat-sensitive compounds while accelerating evaporation. This principle enables efficient concentration without thermal degradation.

Enhanced Circulation

Rotating flask creates constant surface renewal for faster evaporation

Low-Temperature Process

Reduces thermal stress on valuable compounds and samples

Solvent Recovery

Up to 95% solvent recovery reduces costs and environmental impact

Smart Rotovap Buyer's Guide

Not all evaporators are created equal. As you prepare to buy rotovap equipment, consider these key factors:

Critical Selection Factors

Precision control—the ability to maintain exact vacuum levels and rotational speeds for consistent results. Look for units with digital controllers that maintain pressure within ±1 mbar. High-quality condensers with large surface areas make a crucial difference in solvent recovery efficiency too. An investment in a precision instrument pays dividends in reproducible results.

For many labs, purchasing a laboratory rotary evaporator provides the perfect balance between performance and affordability. When space is at a premium, the compact size of a mini rotary evaporator might be essential.

"Life-Changing Efficiency"

"Our lab used to process 5 solvent samples per day manually. After installing a 5L rotovap system, we increased throughput to 20 samples daily with only one technician! The ROI calculation was simple—it paid for itself in solvent recovery alone within 10 months."

Dr. Elena Rodriguez

Head of Chemistry, BioPharma Solutions

Saving Money Is The Last Word, And It Is Worth Investing In Buying!

A quality rotovap isn't an expense—it's an investment with measurable returns. Consider these figures:

According to the Global Lab Efficiency Consortium, labs investing in premium equipment experience 40% fewer process failures and 23% longer equipment lifespans. When you factor in technician time saved through automation and reduced solvent purchases, the extra investment typically pays for itself within the first year. Downtime—the silent budget killer—drops significantly with reliable systems.

Finding Your Perfect Rotovap Size

Choose the capacity that fits your current needs while considering room for growth:

| Capacity | Sample Volume | Best For | Cost Range | Featured Model |

|---|---|---|---|---|

| Small (1-2L) | Up to 0.5L | R&D, quality control | $2k - $5k | Mini Rotary Evaporator |

| Medium (5L) | 1-3L | Small production, university labs | $5k - $9k | 5L Rotary Evaporator |

| Large (10-20L) | 3-10L | Medium production runs | $10k - $20k | 10L Rotary Evaporator |

| Industrial (30-50L+) | 10L+ | Large-scale production | $20k+ | 50L Rotary Evaporator |

Pro Tip: If you're between sizes, go up! An oversized flask on a larger rotovap works fine for smaller batches, but you can't safely exceed the capacity of a smaller unit.

Production Tip: For continuous operation, consider dual condenser systems. While costing 20% more upfront, they eliminate downtime during condenser defrosting cycles.

Revolutionize Your Lab Today

The question isn't whether you should buy rotovap equipment—it's which specifications will maximize your long-term efficiency.

E-mail:

WhatsApp:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Related blogs

You May also like

Rotary Evaporator Machine - Complete Guide

Comprehensive guide to rotary evaporator machines covering working principles, components, applications, technical specs, and tips for selecting the right mod...

Read MoreExplosion Proof Rotary Evaporator - Your Lab's Safety Guardian

Discover why explosion proof rotary evaporators are essential lab safety equipment. Learn how they prevent solvent fires, save costs long-term, and explore mo...

Read MoreEthanol Rotary Evaporator Guide

Discover how ethanol rotary evaporators work, their cost-saving benefits, and how to choose the right model. Learn solvent recovery techniques, safety practic...

Read More